The EI-Analytic platform from Erbessd is a powerful online condition monitoring solution. That turns real-time data from Phantom wireless sensors into actionable insights. Designed for predictive maintenance. It provides maintenance teams and reliability engineers with the tools to monitor vibration, temperature, current, and RPM across critical assets anytime, anywhere.

By combining wireless condition monitoring with cloud-based dashboards, alerts, and analytics. EI-Analytic helps reduce unplanned downtime, improve equipment reliability, and streamline maintenance programs.

Key Features & Benefits

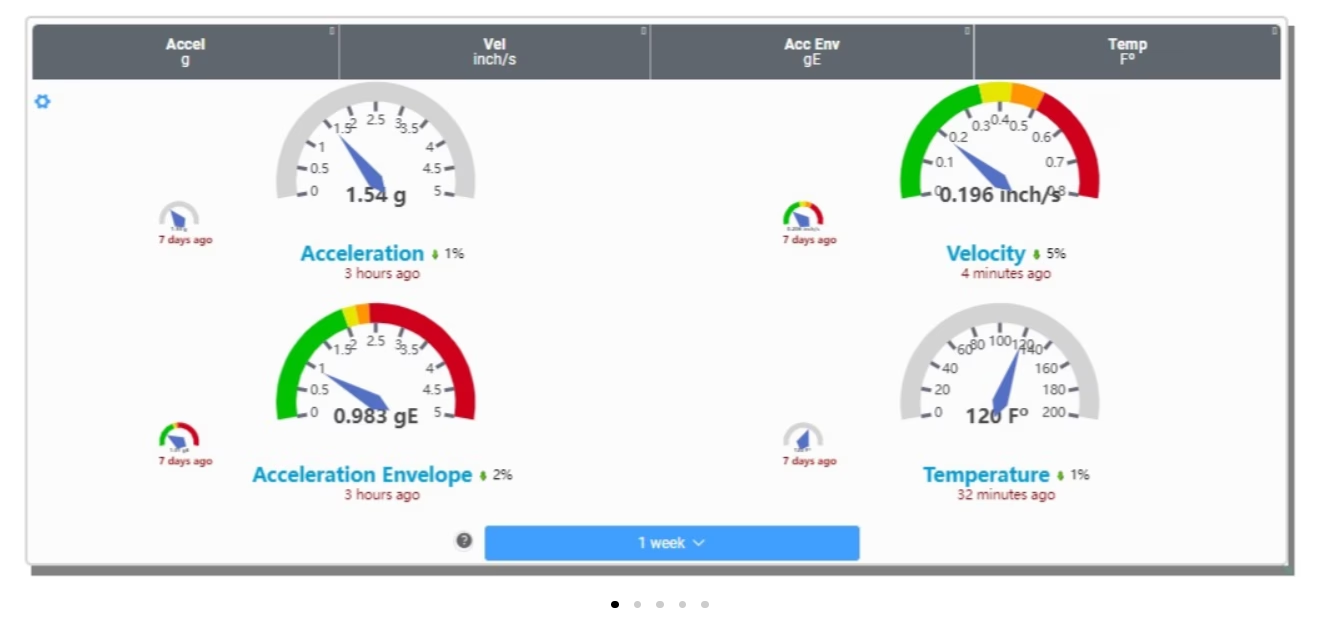

Real-time monitoring – track vibration, temperature, current, and speed across multiple machines.

Alarm notifications – receive instant alerts when conditions exceed safe thresholds.

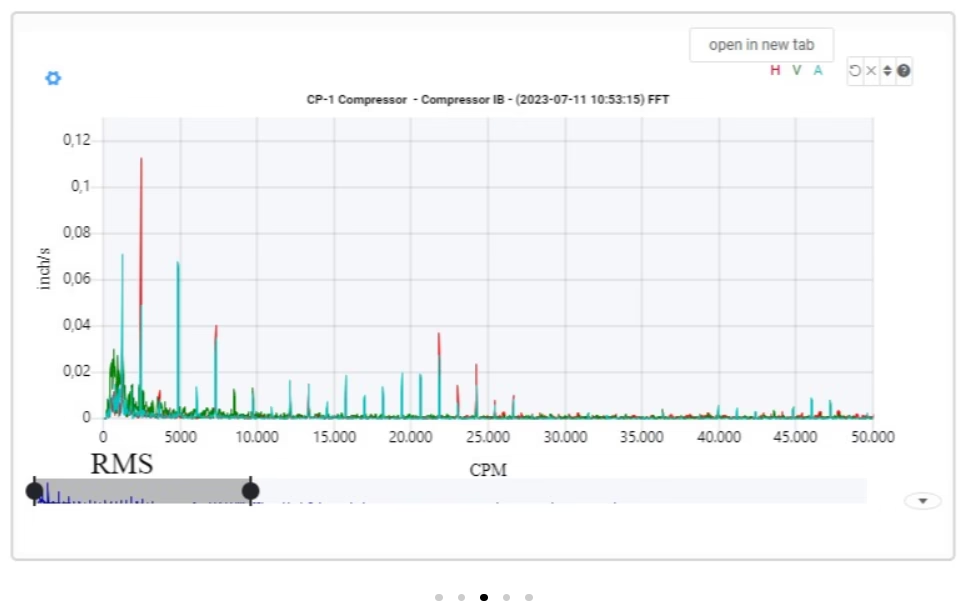

Online vibration analysis – built-in FFTs, waveforms, harmonics, orbits, and sideband tools for accurate fault detection.

Machine learning thresholds – adaptive alarms that learn normal operating ranges, reducing false positives.

Dashboard visualisation – “Bad Actor” lists, trend charts, and machine health scores make it easy to focus on problem assets.

Collaboration & data sharing – share machine data with your team, set access levels, and make decisions faster.

Flexible integration – supports Modbus, OPC UA, and MQTT, ensuring seamless SCADA and IIoT connectivity.

Cross-platform access – available on PC, tablet, and mobile for remote condition monitoring.

Applications

The EI-Analytic online condition monitoring system is ideal for:

Mining & heavy industry – monitor conveyors, crushers, mills, and pumps.

Water & wastewater utilities – track pumps, blowers, and remote assets.

Manufacturing – monitor motors, gearboxes, and production line equipment.

HVAC & commercial facilities – improve reliability of chillers, compressors, and fans.

Oil & gas / hazardous areas – integrate with ATEX-rated Phantom sensors for safe operation in explosive environments.

How It Works

Sensors: Phantom vibration, temperature, current, RPM, and general-purpose sensors collect real-time data.

Gateway: Phantom Gateways transmit data via Zigbee to the cloud or local servers.

Platform: EI-Analytic visualises the data with dashboards, alarms, and analytics for proactive decision-making.

Why Choose EI-Analytic

Complete solution – works seamlessly with Phantom wireless sensors and gateways.

Scalable – start with a few machines and expand plant-wide.

Proven integration – compatible with SCADA, PLC, and IoT platforms.

Local support – Metromatics provides Australian sales, service, and technical support to ensure smooth deployment and long-term success.

Move beyond reactive maintenance with EI-Analytic Online Condition Monitoring.

Contact Metromatics today. Learn how this powerful platform can deliver predictive maintenance insights and keep your critical assets running reliably.