As drones become increasingly critica. Especially, in defence, inspection, emergency services, agriculture and industrial operations. The reliability of their airframes is more important than ever. A drone may look intact after a crash or hard landing. However, internal structural damage can significantly affect vibration levels, lift performance and long-term safety.

Researchers from Poznan University of Technology recently explored this challenge. Achieved by using Dewesoft data acquisition technology, comparing a healthy drone frame against one that had previously experienced a crash. Their findings highlight why high-precision vibration measurement is essential for drone integrity, maintenance programs and design validation.

This blog summarises the engineering problem, the test methodology, the key insights, and why Dewesoft DAQ is uniquely suited to structural testing of UAVs.

The Engineering Challenge: Hidden Damage in Drone Airframes

Drone frames are lightweight and compact, but they’re also subject to:

- high-frequency vibration from motors

- rapid manoeuvres

- impacts

- thermal cycling

- fatigue loading

Even small cracks or shifts in geometry can change how vibrations travel through the structure.

To the naked eye, the drone might appear “fine”—but the vibration signature tells the real story.

This is where structural testing becomes critical.

Test Objective: Healthy Frame vs Crash-Damaged Frame

The researchers wanted to answer one question:

Does previous crash damage measurably change the vibration behaviour and performance of a drone frame?

To test this, they instrumented two frames:

- Frame A — Healthy

- Frame B — Damaged (after-crash)

In addition, both were mounted, instrumented and run through the same measurement procedure.

🎛️ Measurement Setup Using Dewesoft DAQ

The team used Dewesoft data acquisition systems paired with high-accuracy accelerometers to capture:

- vibration amplitude

- frequency response

- acceleration peaks

- lift performance

- motor behaviour under identical conditions

Dewesoft DAQ provided critical advantages:

✔ High sampling rates

Capturing fast dynamic events from propellers and motors.

✔ Synchronised vibration and performance data

Allowing direct comparison between structural response and lift loss.

✔ Easy sensor integration

Ideal for lightweight UAV test setups where space is limited.

✔ Clean, noise-free recordings

Also essential when analysing small changes caused by micro-damage.

✔ DewesoftX software for analysis

FFT, time-domain analysis, spectral comparison and reporting.

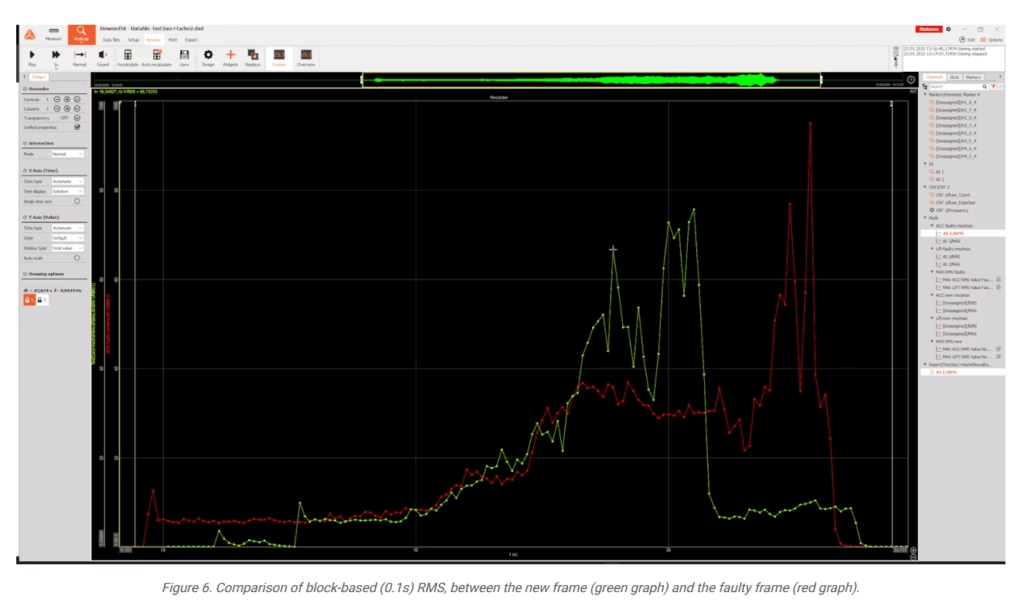

Key Findings: Damage Increases Vibration by Around 22%

The results were clear:

- The damaged frame exhibited significantly higher vibration levels—around 22% greater than the healthy frame.

- Vibration increased across multiple frequency bands, not just at the motor drive frequency.

- Structural stiffness changes altered the resonant behaviour of the airframe.

- Lift performance decreased, meaning the drone had to work harder to produce the same thrust.

In simple terms:

The damaged drone didn’t just vibrate more. Its ability to fly efficiently was reduced.

This is critical for real-world applications where:

- flight times matter

- battery life is limited

- accuracy and stability are essential

- reliability is mandatory

- safety is a priority (especially in defence or public environments)

Why This Matters for Drone Operators and Manufacturers

1. Crash damage is not always visible

Hairline cracks and internal structural failures can stay hidden while altering vibration behaviour.

2. Vibration affects performance and safety

Higher vibration means:

- more battery drain

- increased controller workload

- shorter component lifetime

- reduced flight stability

- risk of catastrophic in-flight failure

3. DAQ provides a quantifiable health check

Instead of guessing, engineers can use data acquisition to:

- compare frames

- verify structural repairs

- optimise manufacturing

- improve design stiffness

- build predictive maintenance programs

Dewesoft DAQ: The Ideal Tool for UAV Structural Testing

Metromatics supplies Dewesoft data acquisition solutions across Australia and New Zealand. This case study highlights why they are ideal for drone testing:

- Compact systems suitable for UAV test rigs

- Support for accelerometers, strain gauges, microphones and more

- High sample rates for analysing propeller and motor harmonics

- Powerful FFT and modal analysis tools

- Seamless hardware/software workflow

So whether you’re testing prototypes, validating repairs, or developing UAV performance models. Dewesoft provides the precision and flexibility needed for high-quality drone analysis.

Conclusion

In conclusion, drone testing project shows how even small damage can greatly change vibration behaviour and overall performance. Using Dewesoft DAQ, the engineering team was able to quantify these differences clearly. Therefore, reinforcing the importance of vibration analysis in UAV design, maintenance and post-impact evaluation.

As drones continue to play a larger role in critical applications, data-driven structural insight will become essential. Finally, are you keen to learn more how detecting drone damage with Dewesoft DAQ is achievable? Contact us.