As embedded systems become smaller, smarter, and more power-efficient. Engineers face increasing pressure to integrate precise sensor measurement into devices with extremely limited space and power budgets. Traditional analogue signal conditioning can introduce noise, complexity, and longer development cycles. Especially when working with strain gauge–based load cells.

The QIA128 miniature load cell signal conditioner addresses these challenges. Firstly, with a compact, ultra-low-power design. That allows engineering teams to move seamlessly from early R&D to high-volume production. For designers working in medical devices, robotics, defence, and industrial IoT, this platform represents a major leap forward in embedded sensing.

What Is the QIA128 Miniature Load Cell Signal Conditioner?

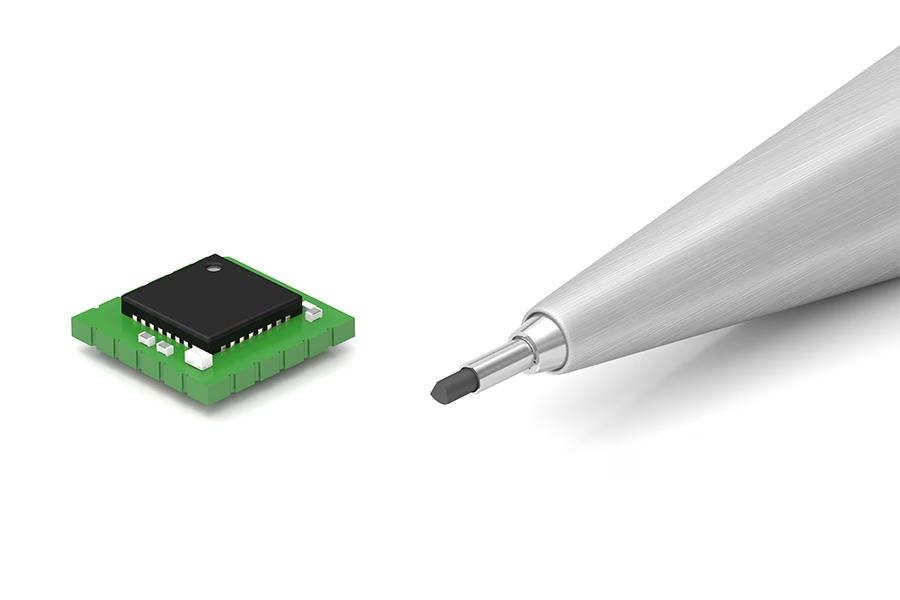

The QIA128 is a miniature digital signal conditioning module. Designed to convert strain gauge bridge inputs into high-resolution digital data over SPI or UART. It integrates amplification, sampling, filtering, and ADC conversion into a single 8 × 8 mm package. Finally, that consumes just 60 mW of power.

Key performance specifications include:

- Sampling Rate: Up to 1300 SPS

- Noise-Free Resolution: Up to 18.4 bits

- Bridge Resistance Support: 350 Ω – 5000 Ω

- Digital Output: SPI or UART

- Ultra-Compact Size: 8 × 8 mm

- Power Consumption: 45 mW

This combination makes it ideal for embedded applications where accuracy, low power, and space efficiency are critical.

Why Digital Signal Conditioning Matters for Modern Embedded Systems

Traditional analogue load cell conditioning requires multiple components. Such as op amps, filters, ADCs, calibration circuitry—and careful noise management. As cables get longer, analogue noise increases, and board space disappears quickly.

A miniature load cell signal conditioner like the QIA128 eliminates this complexity by providing:

- A fully digital signal path

- Built-in high-resolution sampling

- Noise-resistant outputs (SPI/UART)

- Consistent, repeatable performance

The result is faster development, cleaner data, and simpler integration into microcontrollers and embedded processors.

A Unified Platform for R&D and Production: QIA128 Development Kit vs OEM Module

One of the greatest engineering advantages of the QIA128 is its single, unified firmware and performance profile across both development and OEM versions. This makes it easy to prototype first—and scale later—without requalification or code changes.

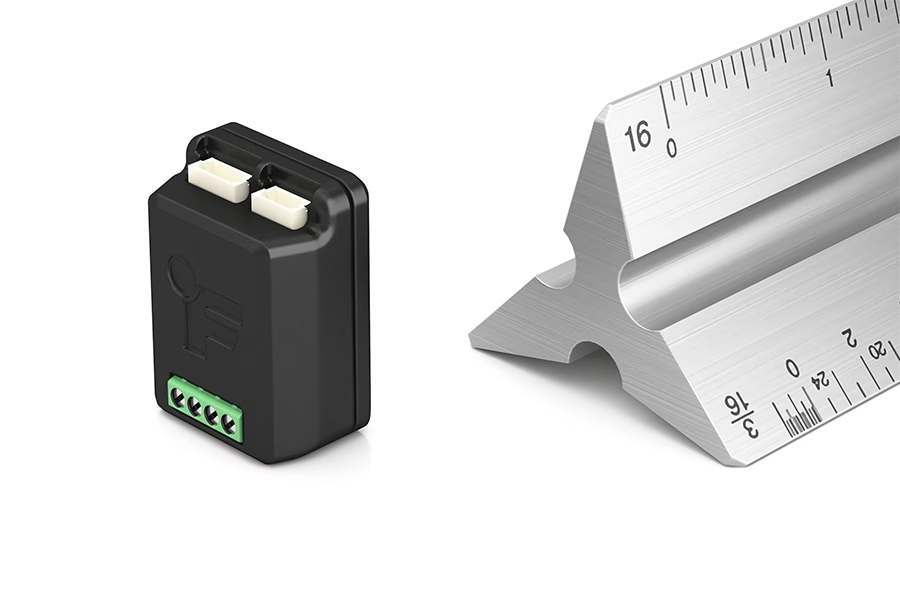

QIA128 Development Kit – Fast Prototyping and Sensor Evaluation

The Development Kit (28.1 × 21.5 mm) is designed for early-stage evaluation:

- Rapid integration into lab equipment

- Easy access to pins and headers

- Ideal for firmware testing and proof-of-concept builds

Engineers can validate performance, optimise firmware, and confirm sampling behaviour before committing to a final design.

QIA128 OEM Module – Ultra-Compact Conditioning for High-Volume Designs

Once testing is complete, the miniature 8 × 8 mm OEM module can be soldered directly to the final PCB:

- Perfect for medical devices, robotics, and wearables

- Designed for low-cost, high-volume manufacturing

- Same firmware = no redesign, no rework, no new certification

This smooth transition from R&D to production reduces risk and accelerates time-to-market.

Key Advantages of a Miniature Load Cell Signal Conditioner

High-Resolution, High-Speed Sampling (1300 SPS, 18.4-Bit NFR)

Firstly, the QIA128 captures fast, accurate, quiet digital data. Suitable for applications requiring precision load measurement and dynamic sensing.

Ultra-Low Power Consumption for Embedded and Battery-Powered Devices

With a footprint of just 45mW, the module is ideal for portable instruments, body-worn devices, and remote industrial sensors.

Support for 350–5000 Ω Strain Gauge Bridges

This wide compatibility allows engineers to integrate a broad range of load cells—including low-power and specialty micro-load sensors.

Noise-Free Digital Output via SPI or UART

Digital communication avoids analogue noise issues, enabling longer distances (UART) or higher-speed chip-to-chip data transfer (SPI).

UART vs SPI for Load Cell Signal Conditioning: Which Should You Use?

Both communication protocols are supported, giving engineers flexibility based on system architecture.

UART

- Asynchronous

- Excellent for longer cable lengths

- Simple and robust

- Ideal for MCU or PC interfaces

SPI

- Synchronous, high-speed

- Best for short-distance, embedded communication

- Low overhead and low latency

- Preferred for high-speed sampling systems

Choosing between them depends on cabling distance, microcontroller architecture, and system layout.

Where Miniature Load Cell Signal Conditioners Fit in Australian Applications

The QIA128 is designed for industries where high accuracy is needed in extremely compact form factors.

Medical Devices and Wearable Instrumentation

- Handheld surgical tools

- Physiological monitoring devices

- Wearable health sensors

- Miniature implantable measurement systems

Robotics, Actuators, and Compact Force Measurement

- End-effector force feedback

- Actuator load measurement

- Precision robotic assembly

- Compact force/torque control

Defence, Aerospace, and Lightweight Embedded Systems

- Portable soldier systems

- UAV/UGV sensing modules

- Aircraft instrumentation

- Structural and environmental monitoring

Industrial IoT and Low-Power Monitoring Nodes

- Low-power sensor nodes

- Structural health monitoring

- Miniaturised test equipment

- Remote load measurement

Need Multi-Channel Conditioning? Consider the QIA125 Digital 3-Channel SPI Module

For applications requiring multiple load cells or redundant measurements, the QIA125 offers:

- Three-channel amplification

- Low-power operation

- High-speed digital SPI output

- A scalable expansion path for multi-sensor systems

This makes it ideal for robotics, instrumentation, and industrial systems needing more than one channel.

Conclusion: The Future of Embedded Sensing Is Compact, Digital, and Low Power

The QIA128 miniature load cell signal conditioner provides high-resolution sampling. It also has ultra-low power use and a very compact design. Its unified R&D-to-production workflow ensures a smooth transition for engineers building next-generation sensor-driven devices.

For any project requiring precise, miniature, low-power load cell conditioning, the QIA128 provides an elegant, scalable, and future-ready solution.

Contact Metromatics for QIA128 Dev Kits, and Engineering Support

Metromatics is your local partner for FUTEK QIA128 evaluation, and OEM supply across Australia and New Zealand.

Contact us today for specifications, pricing, or a technical consultation.