This application on Resistance Spot Welding has been kindly provided by our valued supplier FUTEK.

Application Summary

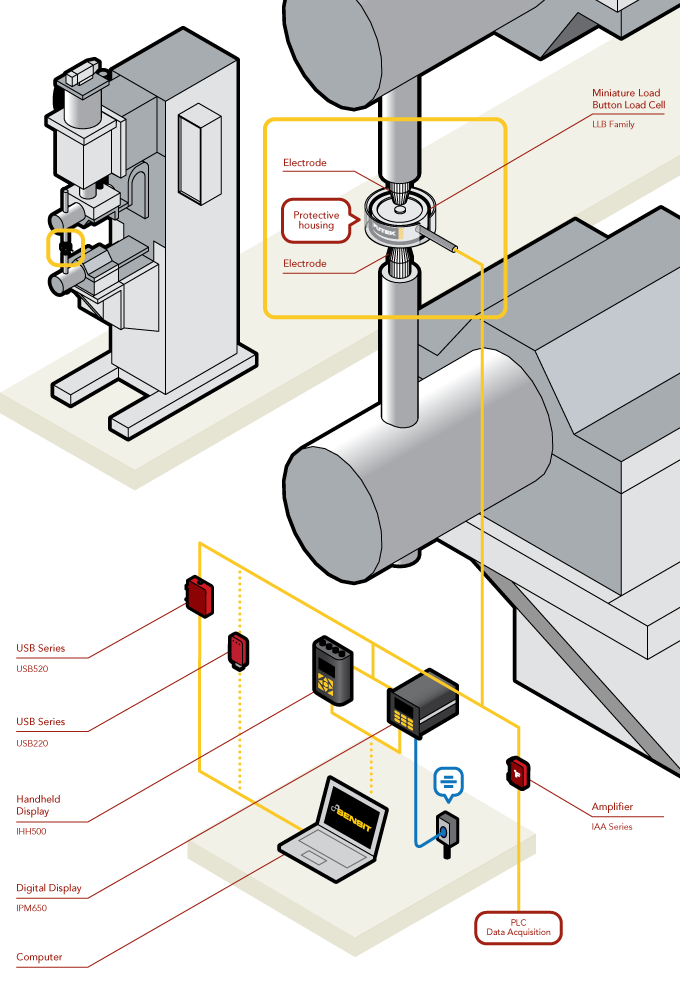

Resistance Spot Welding is a process in which pieces of metal are joined together by the heat created by the electrical resistance of the material combined with the forces applied by the electrode to hold the pieces together. The forces applied by the electrodes are very critical to the process, as the incorrect amount might cause cracks, holes, and failures in the welds. FUTEK’s LLB300 Miniature Load Button helps operators ensure that the welding machine is applying the correct amount of force.

Products in Use

Miniature Load Button (LLB Series) paired with Instrumentation and Software (IAA Analog Amplifier, IHH500, IPM650, USB520 or USB220, and SENSIT™ Test and Measurement Software).

How it Works

- Firstly, Resistance Spot Welding is a process. Secondly, performed on vehicle parts in the automotive industry.

- Resistance Welding machines must apply a specific amount of pressing force with the electrodes. In order to ensure that the machine will apply a proper weld.

- Load Cells measure the pressing force from a Resistance Spot Welding machine.

- In this application, FUTEK’s LLB300 Miniature Load Button is between the electrodes. Therefore, to calibrate the force applied. As force is applied by the machine, the LLB300 will sense the load measurement. It can display the value on FUTEK’s IHH500 Intelligent Digital Hand Held display, FUTEK’s IPM650 Panel Mount Display, or a PC via FUTEK’s USB Solutions.

- Pairing the SENSIT™ Test and Measurement Software with any of FUTEK’s instruments. Provides the user with the ability to data log. Live graph the measurements and store them for calibration history.

- NOTE: We recommend engineers use caution upon installation of the load cell between the electrodes, so as not to damage the LLB’s housing.

In addition, all FUTEK’s illustrations are strictly conceptual – please contact us for more information.