With rising energy costs and increasing pressure to lower carbon footprints, Smart Energy Management Systems for manufacturing have become more important than ever. These systems allow small to medium manufacturing businesses to stay ahead by improving efficiency and reducing costs. This is because this technology helps monitor, analyse and optimise energy use across entire operations.

What Does a Smart Energy Management System For Manufacturing Do?

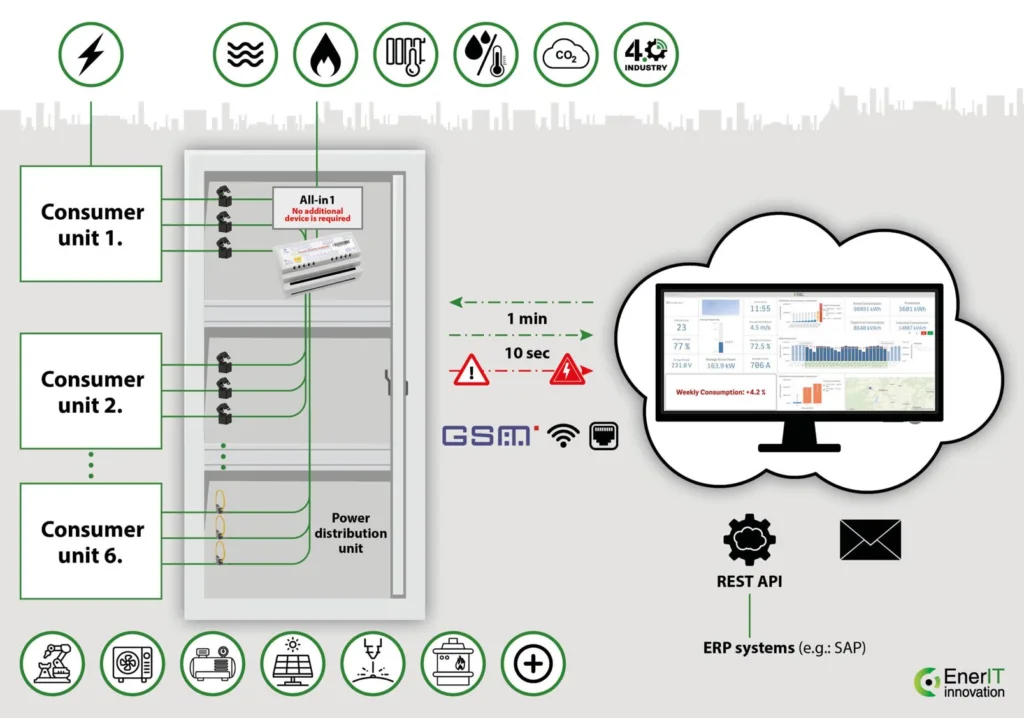

Our Smart Energy Management System provides real-time monitoring of a wide range of electrical and energy-related systems in your building or factory:

- Electricity Consumption – Tracks energy use across different machines and production lines.

- Power Quality – Identifies voltage fluctuations, harmonics, and other issues affecting performance.

- Solar and Battery Performance – Monitors renewable energy sources and battery storage efficiency.

- Lighting and HVAC Systems – Optimises energy use in non-production areas.

- Compressed Air and Pumps – Detects inefficiencies in high-energy equipment.

Data Insights for Smarter Decisions

SEMS does more than just collect data—it turns it into actionable insights:

- Identify Energy Waste – Get real-time alerts for equipment running inefficiently or using power during non-production hours.

- Predictive Maintenance – Detect early signs of wear and tear to prevent costly breakdowns.

- Operational Benchmarking – Compare energy performance across shifts, machines, or locations.

- Automated Reporting – Simplify compliance and energy audits with detailed reports.

How a Smart Energy Management System For Manufacturing Helps Your Business

Our Smart Energy Management System provides measurable benefits that translate into real savings and sustainability:

- Lower Energy Bills – Identify waste and optimise energy use to cut unnecessary costs.

- Improved Operational Efficiency – Reduce downtime with proactive maintenance insights.

- Reduced Carbon Footprint – Use data to support sustainability goals and meet regulatory requirements.

- Data-Driven Decision Making – Make informed choices about upgrades, energy contracts, and process improvements.

- ROI Within Months – Many businesses recover their investment in SEMS within months through energy savings.

Future-Proof Your Manufacturing Business

Manufacturing is evolving, and energy efficiency is key to staying competitive.

A Smart Energy Management System for manufacturing gives you the tools to control costs, improve productivity, and reduce environmental impact. It’s an all in one powerful, easy-to-use platform that allows you to take the next step towards smarter manufacturing.

Contact Us

If you would like to learn more about how our Smart Energy Management System can transform your operation please, contact us.