Welcome to the cutting-edge of diesel generator management: Our Diesel Generator Remote Monitoring System.

Firstly, this solution combines hardware and software. It is set to revolutionise fuel and operational management, ensuring your diesel gensets operate with unparalleled efficiency and reliability.

Optimise Your Operations

Our system is designed to enhance the operation of diesel generators (DG), significantly reducing fuel and operational costs. Achieved by optimising the maintenance schedule. Therefore, preventing service outages and extending the life cycle of your genset but also ensure it runs smoothly and efficiently.

Field of Application

Whether for industrial or residential use, our remote diesel generator monitoring system is perfect for main, reserve, or auxiliary energy sources. It caters to:

- Generator Owners and Operators: Enjoy remote operation supervision, fuel monitoring, and comprehensive data for accounting and predictive maintenance.

- Servicing Companies: Benefit from detailed diagnostics, maintenance scheduling, and timely servicing.

- Manufacturers: Gain insights into genset operation, engine health, and overall diagnostics to refine product design.

Advanced Monitoring Hardware

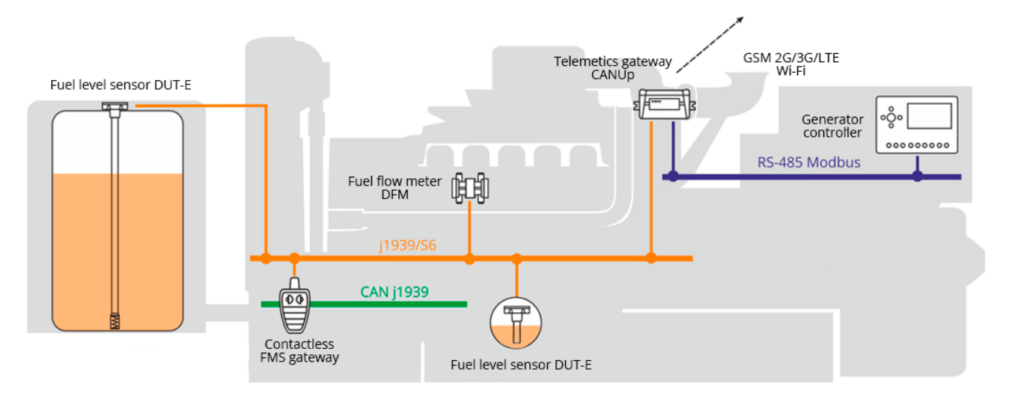

Our system utilises cutting-edge sensors and converters, including:

- Fuel level sensors

- Fuel flow meters

- I/O modules

- Modbus RTU data converters

- CAN bus readers for engine data

- Telematics gateway for comprehensive data transmission

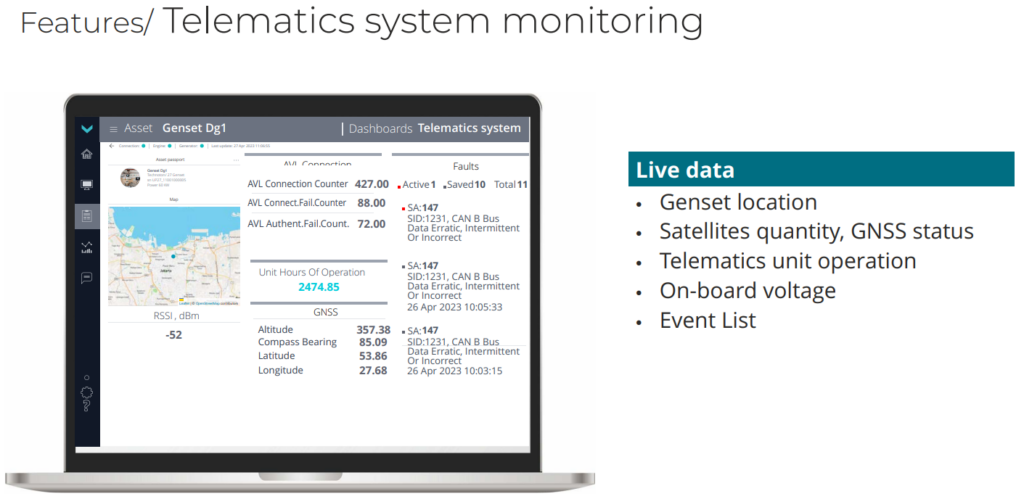

Connected via J1939/S6 interface or S7 Technology for wireless communication, these components ensure real-time, accurate data collection and reporting.

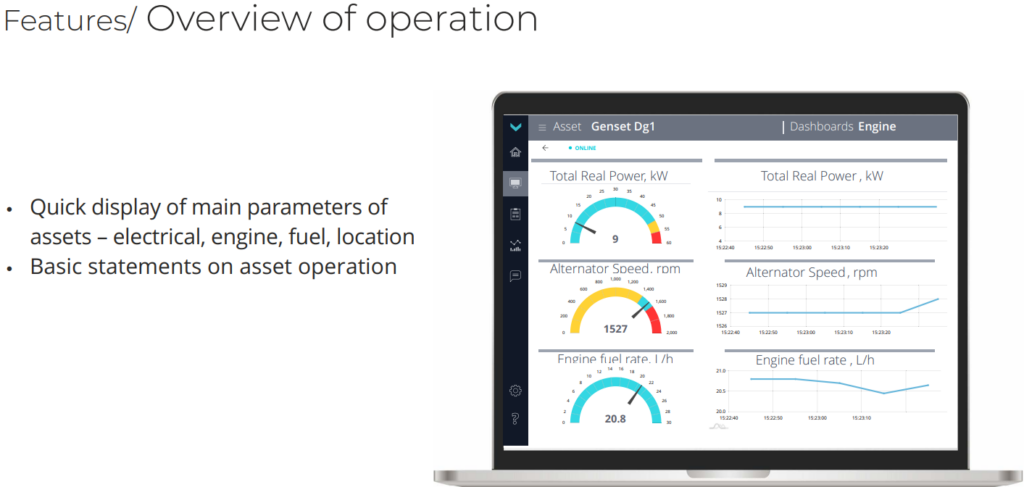

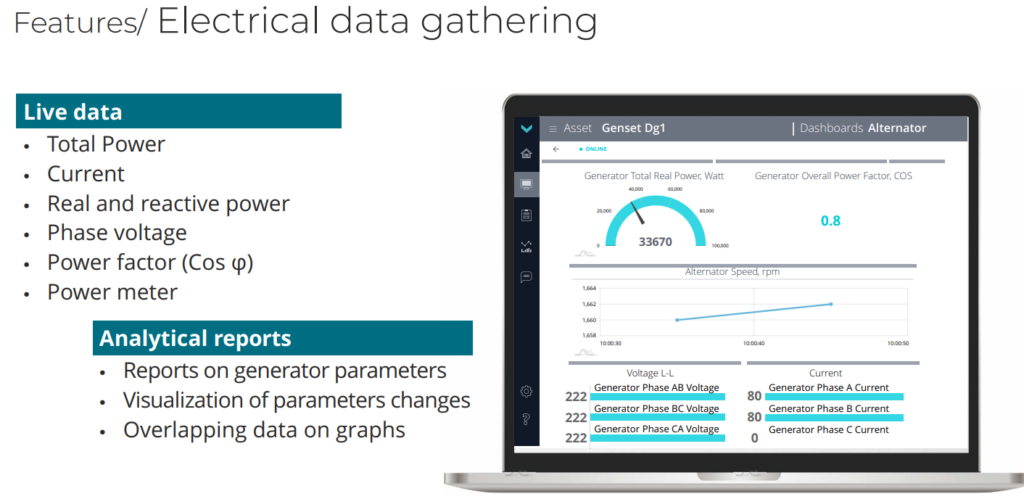

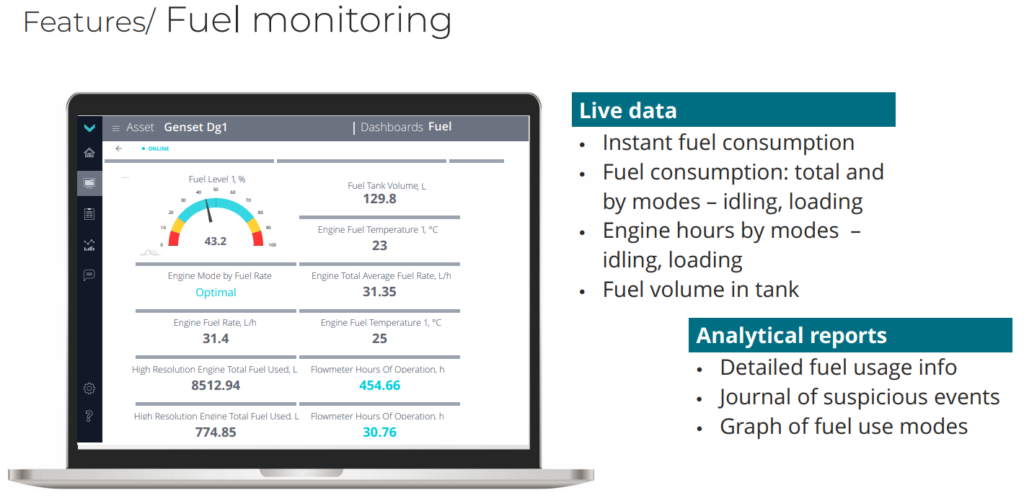

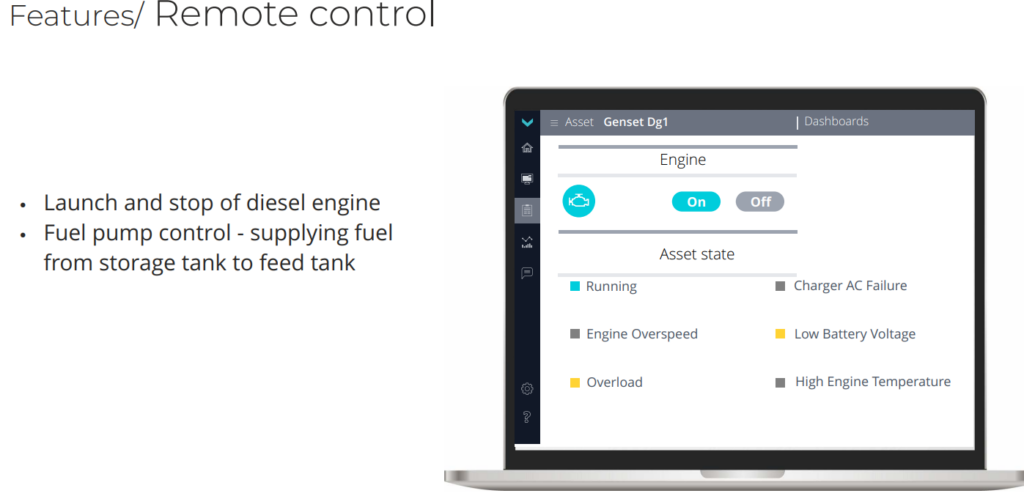

Remote Monitoring Online

Experience real-time monitoring through our web-based platform, accessible 24/7 from any PC or smartphone with an internet connection. Our platform provides instant access to up to 400 operating parameters, allowing for detailed analysis and report generation on fuel consumption, power generation, and engine workloads.

Event Detection and Automation

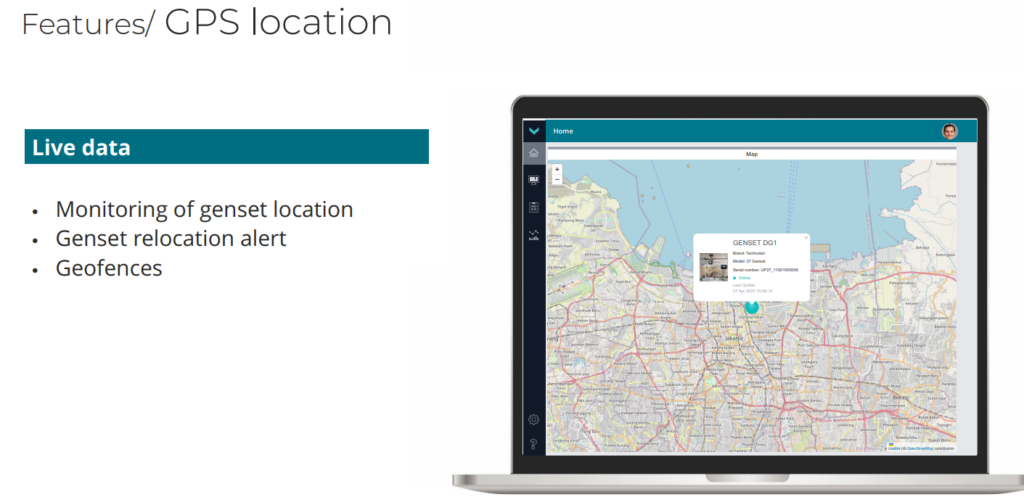

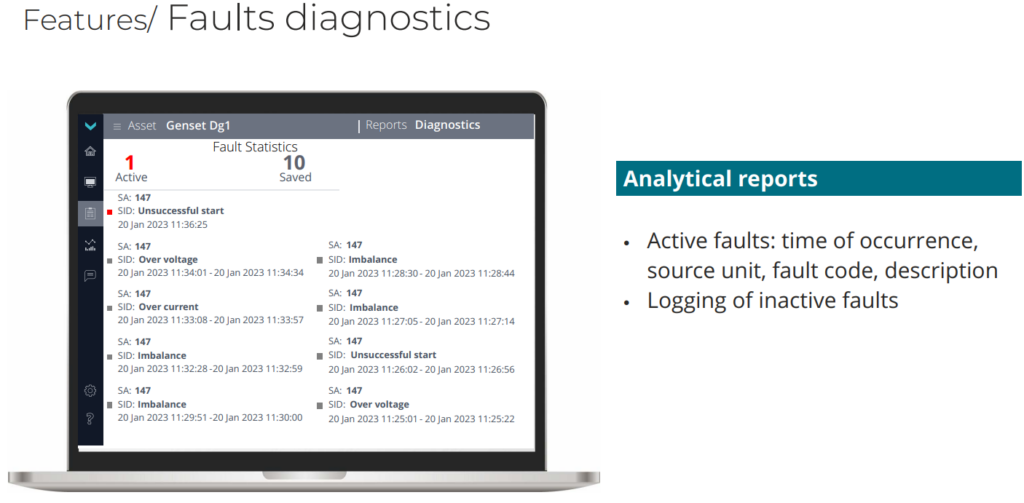

Stay informed with email and SMS notifications on critical events such as engine start/stop, load changes, and potential fuel theft. Our system’s automation capabilities can control fuel supply, ensuring efficient operation and preventing potential issues before they lead to breakdowns.

Metromatics: Your Partner in Generator Monitoring

Our Partner’s solutions are customisable to fit the specific needs of your genset, ensuring you have the tools to monitor and manage your diesel generators effectively. Trust in our system to bring you peace of mind and operational excellence.

Experience the future of diesel generator monitoring today and take the first step towards optimising your energy solutions.

Case Study: Remote Monitoring in Action with a Diesel Generator Monitoring System

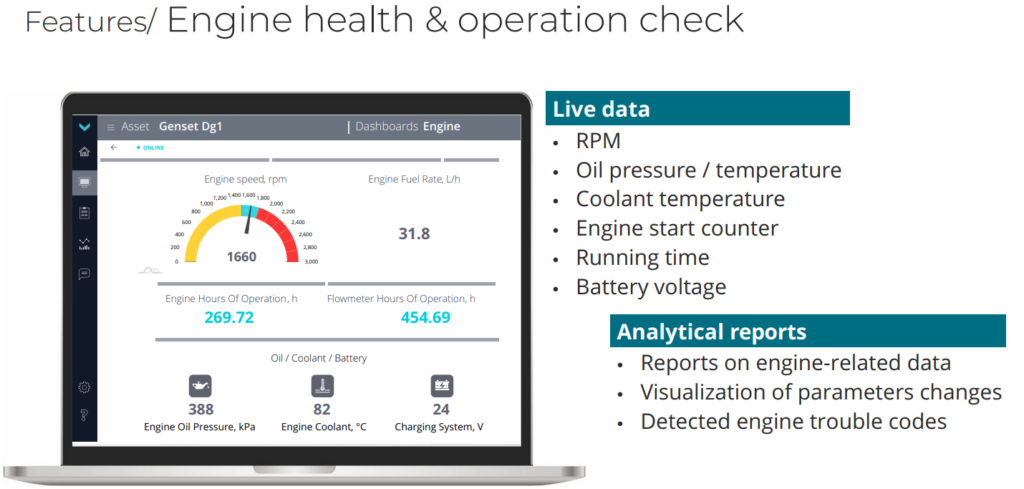

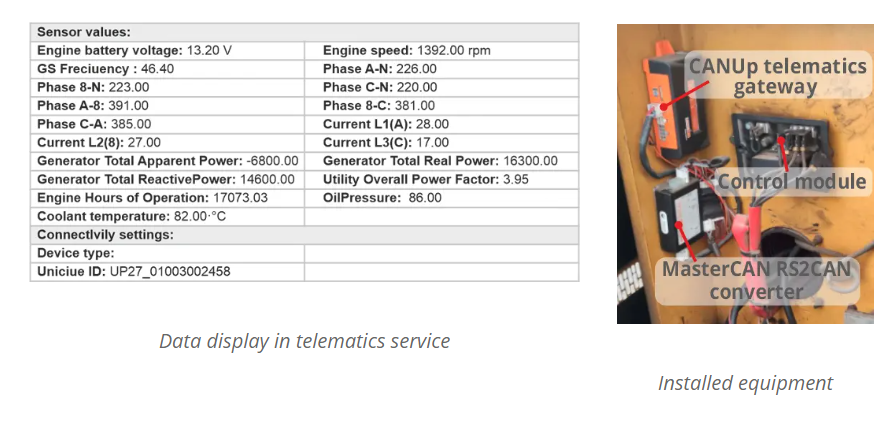

Consider a setup where the diesel generator sets are deployed in remote areas. Therefore, rendering constant visual control an impractical endeavour. The generators, boasting a power output range of 230 to 330 kVA. In addition, managed by controllers from Deep Sea Electronics (DSE). These controllers display critical data like voltage, frequency, current, generated power, coolant temperature, engine oil pressure, engine RPM, and engine run time.

The primary task at hand was to implement a real-time remote monitoring system. This is to oversee performance and plan timely maintenance of these generators. The solution orchestrated involved a monitoring system based on MasterCAN RS2CAN converter and CANUp telematics gateway, channelling data to ORF4 online telematics service. This setup meticulously read and transmitted 92 parameters from the controller to the gateway, which in turn sent operational reports to the online service.

Key operational parameters relayed included alternator operating metrics (voltage, power, current, frequency), diesel engine parameters (speed, coolant temperature, oil pressure, fuel consumption), and a counter for the total operating time of the power generating unit.

Reaping the Benefits: Insights and Actions from Afar

This robust diesel generator monitoring system allowed swift mounting on the diesel genset. The user, sitting miles away, now has insight into the health and operational status of the generator units. Notifications about emergency shutdowns and malfunctions were relayed in real time, marking a monumental stride in proactive maintenance and operational efficiency.

Furthermore, the system’s scalability was evident. Especially, when the installation of a DFM CAN fuel flow meter in the fuel system provided additional data on fuel consumption. Collected data is exportable in .txt or .xls formats for further processing, analysis, and decision-making.

Conclusion

The fusion of diesel generator sets with advanced monitoring systems like the Genset Monitoring System and the usage of genset monitoring devices pave the way for not just uninterrupted power supply. In addition, provide a substantial reduction in operational hiccups and unforeseen maintenance downtimes. As the realm of remote monitoring of diesel generator systems continues to evolve. Facilities nestled in the farthest corners of the globe can now ensure their power systems are operating optimally. Therefore, ensuring a smooth, uninterrupted flow of operations critical to their success.

Finally, ensure your operations run smoothly and uninterrupted with Metromatics at your service. Reach out to us today for local sales, unparalleled service, and support tailored to meet your unique needs.