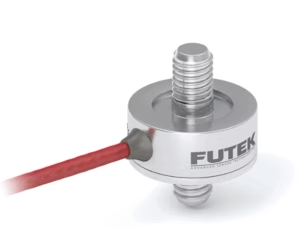

The TRS600’s non-contact design eliminates wear components, ensuring long-term reliability even in continuous high-speed operation. Its integrated encoder also provides precise speed and angle feedback. As a result, it’s ideal for advanced closed-loop control systems. With excellent noise immunity and a robust aluminium housing, this Shaft Rotary Torque Sensor also performs reliably in demanding industrial and research environments. It also easily integrates into DAQ, control, and test systems. As a result, it is a versatile solution for engineers requiring accurate, maintenance-free rotary torque measurement.

Key Features of the TRS600 Non-Contact Shaft-to-Shaft Rotary Torque Sensor:

- Non-contact shaft to shaft design for wear-free, maintenance-free operation

- Torque capacities from 1 Nm to 100 Nm to suit a wide range of applications

- High rotational speed capability, up to 12,000 RPM

- Integrated signal conditioning with amplified ±5 VDC output for easy integration

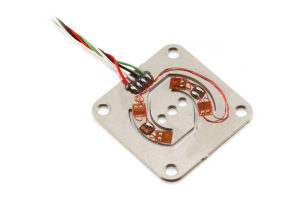

- Strain-gauge based measurement for high accuracy and stability

- Integrated encoder for precise speed and angle feedback

- Excellent noise immunity, ideal for electrically noisy industrial environments

- Robust aluminium housing for durability in harsh applications

- Wide operating temperature range (approx. –25 °C to +80 °C)

- Suitable for dynamic torque measurement in motors, robotics, automation, and aerospace test systems

Applications of the TRS600 Non-Contact Shaft-to-Shaft Rotary Torque Sensor:

- High-speed motor and drivetrain testing

- Electric motor efficiency analysis and performance benchmarking

- Robotics and automation systems requiring real time torque feedback

- Aerospace test rigs, actuators, and propulsion component evaluation

- Automotive engineering, including EV powertrain and transmission testing

- Industrial machinery monitoring for torque, speed, and load conditions

- Pump, compressor, and turbine testing under dynamic loads

- Research and university labs conducting mechanical and mechatronics studies

- Servo motor control loops that need precise torque, speed, and angle feedback

- Endurance and quality assurance testing of rotating components

FAQs – FUTEK TRS600 Shaft Rotary Torque Sensor

- What advantages does the non contact design provide?

The TRS600 uses a non contact signal transmission method, eliminating wear on internal components. As a result it significantly longer service life, reduced maintenance, and reliable performance at high rotational speeds. - What signal output does the TRS600 provide?

This sensor includes built in signal conditioning and also outputs an amplified ±5 VDC signal. As a result, this sensor is easy to integrate into DAQ systems, controllers, and test equipment without requiring an external amplifier. - Can the TRS600 handle high speed applications?

Yes. The TRS600 is made for rotational speeds up to 12,000 RPM. As a result, it’s suitable for EV drivetrains, high performance motors, aerospace tests, and other dynamic applications.

4. Is the TRS600 compatible with Metromatics’ instrumentation and DAQ systems?

Absolutely. Its amplified voltage output integrates easilly with Metromatics’ signal conditioning, DAQ modules, embedded systems, and custom engineered solutions. To talk to an expert about setting up a fully custom solution, please contact us.