Key Features & Benefits of the Sub-Miniature Donut Load Cell LTH150

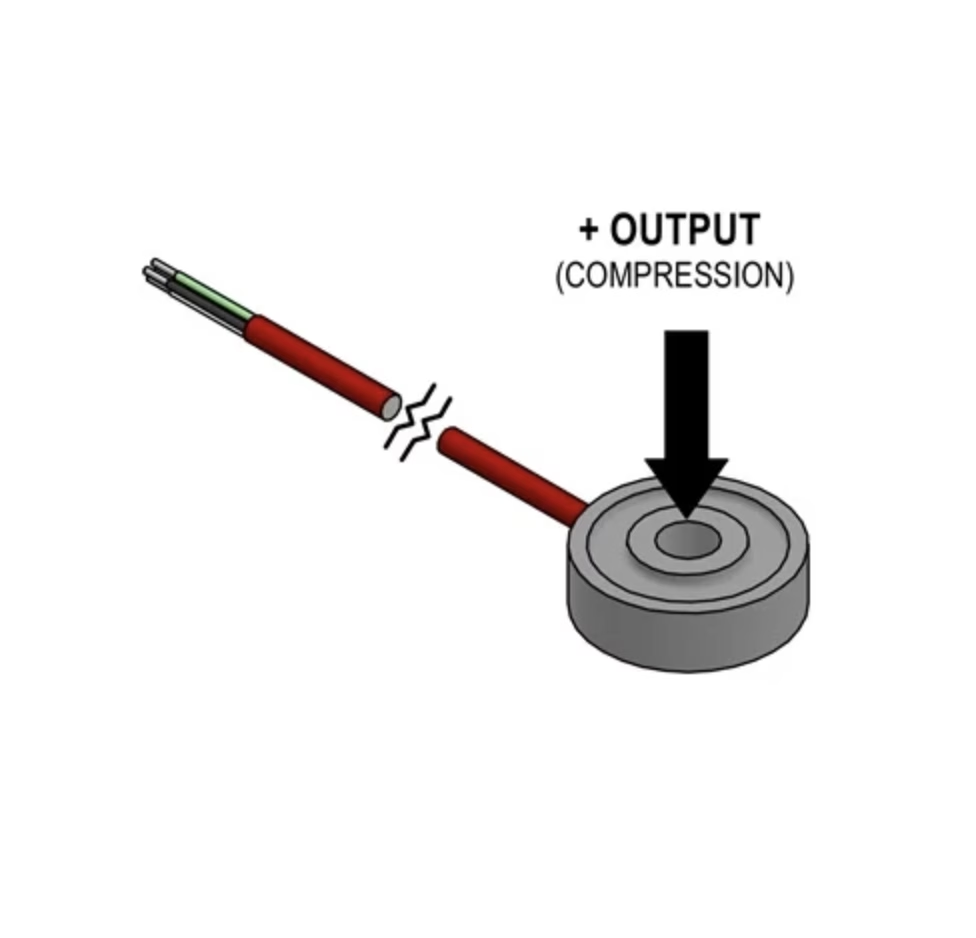

True Through-Hole or Donut Design – Allows a load path (shaft, bolt, rod, etc.) to pass through the center, ideal for applications like measuring bolt preload or clamping force.

Ultra Compact / Low Profile – Height only ~0.16 in (4.1 mm), outer diameter ~0.50 in (12.7 mm).

Wide Capacity Range – Available in capacities from 5 lb up to 250 lb (≈ 22 N to 1,100 N).

Low Deflection & Fast Response – Deflection ~0.0006 in (≈ 0.015 mm) at rated load ensures fast, accurate readings.

Good Overload Protection – Safe overload rating ~150% of rated output to help protect against transient overloading.

Precision Performance – Nonrepeatability ±0.1% of RO, nonlinearity and hysteresis per spec table.

Rugged Construction & Good Environmental Suitability – 17-4 PH stainless steel body, IP64 protection, operating temperature –60 to +200 °F (–51 to +93 °C).

Low Power & Compact Wiring – 1000 Ω bridge resistance, 34 AWG 4-conductor braided cable, 5 ft length standard.

Technical Specifications of the Sub-Miniature Donut Load Cell LTH150

| Specification | Detail |

|---|---|

| Capacities | 5, 10, 25, 50, 100, 150, 250 lb (≈22 to 1,100 N) |

| Rated Output | ~2 mV/V nominal for many models |

| Nonlinearity / Hysteresis | According to spec table, typically ±0.5% for many models |

| Nonrepeatability | ±0.1% RO |

| Safe Overload | 150% of RO |

| Bridge Resistance | ~1000 Ω nominal |

| Material | 17-4 PH stainless steel |

| Deflection | ~0.0006 in (0.015 mm) nominal |

| Operating Temperature | –60 to +200 °F (–51 to +93 °C) |

| Compensated Temperature | 60 to 160 °F (15 to 71 °C) |

| Cable / Connection | 34 AWG, 4-conductor braided polyester, 5 ft standard |

| Weight | ~0.02 lb (≈9.1 g) |

| IP Rating | IP64 |

Typical Applications of the Sub-Miniature Donut Load Cell LTH150

Measuring bolt preload / clamping forces

Inline compression sensing where a structural member must pass through the sensor

Load washers and compression measurement in space-constrained systems

Integration into machines, fixtures or assemblies where conventional load cells cannot be placed

OEM, robotics, medical devices, and automation systems with tight packaging constraints

Why Choose the Sub-Miniature Donut Load Cell LTH150

True Sub-Miniature Donut Load Cell – ideal when you need a load sensor with a through-hole and minimal height.

Compact & Accurate – performance without sacrificing footprint.

Overload Protection & Durability – designed to withstand real-world handling.

Environmentally Robust – stainless steel body, IP64 sealing, wide temperature range.

Support & Calibration – Metromatics can help you choose the right variant, calibrate, integrate, and verify your application.

Sub-Miniature Donut Load Cell LTH150 Models

Item | Load Capacity | Inner Diametre cm | Outer Diametre cm | Height cm | Length cm | Width cm | Connection Type |

FSH03959 | 4448.22 N | 0.9525 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH03960 | 2224.11 N | 0.9525 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH03961 | 1112.06 N | 0.9525 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH03962 | 444.822 N | 0.9525 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH03963 | 222.411 N | 0.9525 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH03964 | 4448.22 N | 0.79 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH03966 | 4448.22 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH03967 | 2224.11 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH03968 | 444.822 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH03969 | 222.411 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH03970 | 444.822 N | 0.32 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH04046 | 1112.06 N | 0.79 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH04047 | 444.822 N | 0.79 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH04048 | 222.411 N | 0.79 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH04049 | 1112.06 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH04050 | 2224.11 N | 0.48 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

FSH04051 | 222.411 N | 0.48 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| FSH04615 | 1112.06 N | ||||||

FSH04616 | 222.411 N | ||||||

| QSH01067 | 2224.11 N | 0.48 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

QSH01567 | 2224.11 N | 0.95 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| QSH01754 | 22.2411 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable & Connector |

QSH01861 | 111.206 N | 0.635 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

| QSH02071 | 222.411 N | 0.95 cm | 2.49 cm | 0.71 cm | 2.49 cm | 2.49 cm | Cable |

Ordering & Configuration Tips

If you would like to learn more about this product or would like to place an order, please contact us.

When ordering an LTH150, consider:

Inner hole (I.D.) needed to pass your bolt, rod, or shaft — the sensor must fit your load path.

Capacity required — choose a model that exceeds your maximum expected load with margin.

Cable length or custom connector options if the standard 5 ft is too long/short.

Calibration and certification needs (compression calibration, traceability, etc.).

Mounting and alignment — ensure the sensor mounting does not impose side loads or bending moments.