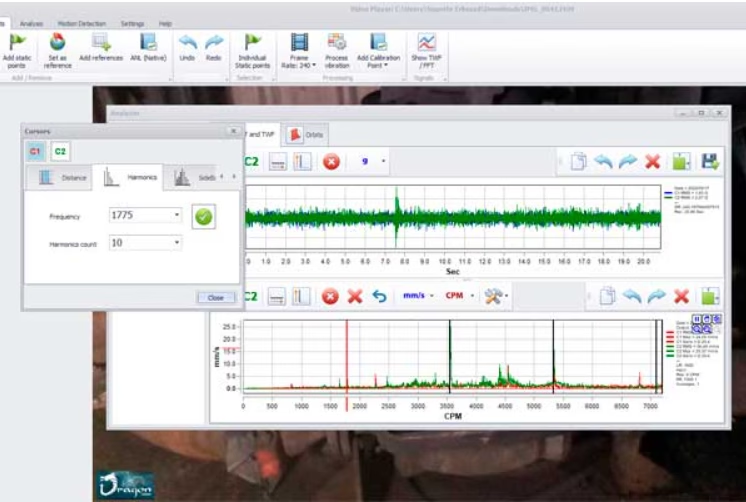

The Erbessd DragonVision is advanced video vibration analysis software. Firstly, that transforms ordinary videos into powerful diagnostic tools. Achieved by using motion amplification technology.

DragonVision magnifies subtle movements in machinery and structures. Therefore, making invisible vibrations visible to the human eye. It allows engineers and analysts to measure vibrations without contact. They can also see Operating Deflection Shapes (ODS) in real time. This removes the need for complex sensor setups.

DragonVision captures and processes high-frame-rate video. It detects small mechanical movements and turns them into measurable vibration signals. The result is a clear and easy view of how machines or structures act under load. This helps maintenance teams and engineers find issues like imbalance, misalignment, looseness, and resonance before expensive failures happen.

Key Features

Motion Magnification & Deflection Analysis: Amplifies microscopic movements in video recordings to reveal the true dynamic behavior of assets.

Non-Contact Measurement: Perform accurate vibration and displacement analysis without installing accelerometers or proximity sensors.

Advanced Calibration Tools: Choose from amplitude (ANL), RMS, or distance calibration modes to correlate video motion with physical vibration levels.

Target-Based Analysis: Define specific regions or points of interest for precise monitoring and comparison across time.

Export & Reporting: Make visual reports and export waveforms, FFT spectra, or processed videos. Use these in DigivibeMX and other analysis software.

Wide Camera Compatibility: Works with most high-speed cameras, industrial cameras, and even smartphones. It captures movements as small as 2.5 µm.

Comprehensive Filtering & Stabilization: Includes anti-aliasing filters, phase simulation, and motion stabilization to enhance accuracy.

Benefits

Instant Insight: See how your machine truly moves — ideal for diagnosing complex vibration problems quickly.

Reduced Downtime: Identify mechanical faults early and plan corrective actions before failure.

Cost-Effective: Lower setup costs by reducing reliance on multiple vibration sensors.

Versatile: Suitable for rotating machinery, structures, piping systems, and even large civil assets like bridges or towers.

Enhanced Communication: Visualise and share results easily with maintenance teams, management, or clients.

Typical Applications

Industrial Equipment Diagnostics: Detect misalignment, imbalance, and resonance in motors, pumps, fans, compressors, and gearboxes.

Structural & Civil Engineering: Evaluate bridge deflection, tower vibration, and building oscillation.

Research & Development: Validate prototypes, perform modal analysis, and visualise structural dynamics.

Training & Education: Demonstrate vibration principles and operating deflection shapes in an interactive, visual format.

Finally, DragonVision revolutionises how engineers perform vibration analysis. As a powerful video vibration analysis software, it bridges the gap between visual observation and quantitative measurement. Therefore, turning any camera into a precision diagnostic instrument. With DragonVision, you don’t just measure vibration; you see it.

To find out more, contact Metromatics today.