This application note on Robotic Arm Sensors has been provided by our supplier FUTEK.

Application Summary Robotic Arm Sensors

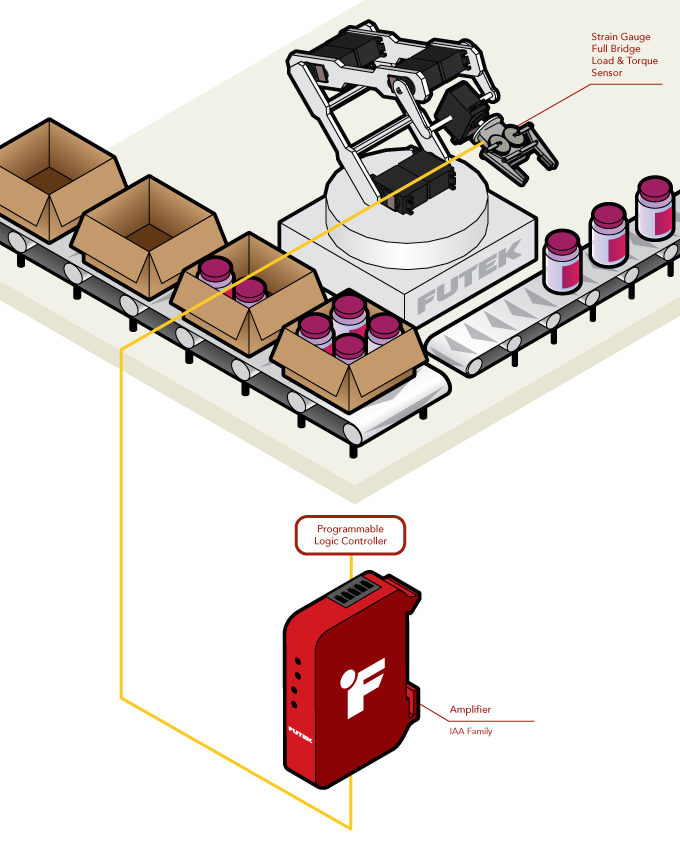

Industrial robots make assembly lines more efficient and reliable – thanks to Robotic Arm Sensors. Firstly, when paired with any full-bridge strain-gauge-based sensor. Operators can use Futek’s IAA amplifiers to send clear, clean signals to logic controllers governing the assembly line.

Products in Use

A strain-gauge, full-bridge multi-axial sensor that measures torque and load paired with the IAA100 (voltage) or IAA200 (current).

How it works

Firstly, in order to automate an industrial robotic arm. Control engineers will need to program a PLC to specify response triggers. As shown in the diagram, a full-bridge strain-gauge-based load and torque sensor resides within the claw of the robotic arm. Therefore, measuring the torque and load of an object. In addition, where a multiple channel sensor is being utilised, the operations engineer will require one IAA amplifier per channel output.

Futek’s IAA Series amplifies the mV/V signal coming from the strain-gauge-based sensor. The output of the IAA amplifier will produce an accurate low noise signal to the PLC , which completes the feedback loop.

For example products depicted in the diagram are: – A strain-gauge, full-bridge multi-axial sensor which measures torque and load, paired with the IAA100 Analog Amplifier with Voltage Output or IAA200 Analog Amplifier with Current Output.

Just one more from the repertoire of Futek’s impressive array of applications!

Finally, for more information on FUTEK Sensor range in Australia or New Zealand, contact us.