Choosing a fuel flow meter requires careful thought to ensure precise measurement and reliable performance for your specific application. Whether you’re monitoring fuel consumption, measuring mass flow rates, or tracking volumetric flow rates, the following steps will help guide your decision:

1. Determine the Application Requirements

Start by identifying how you plan to use the fuel flow meter. Is it for vehicles, industrial equipment, or marine vessels? Different types of flow and systems may require specific features, certifications, or flow meters designed for unique conditions.

2. Define Flow Rate and Accuracy Requirements

Determine the fluid flow rates in your system—both minimum and maximum—and the level of accuracy you need. Since engine specifications rarely include flow rate in the supply line, the most effective way to choose a meter is to measure the instant flow rate directly. Choose a model that offers a performance reserve of 20–25% above your expected maximum.

3. Consider Fluid Suitability

Make sure the meter is suitable for the amount of fluid and the type of fuel you are using. Some meters are designed for fuel consumption using specific types like diesel, petrol, or aviation fuel, while others can measure liquids across a broader range. Consider temperature and viscosity limits if your fluid has unique properties.

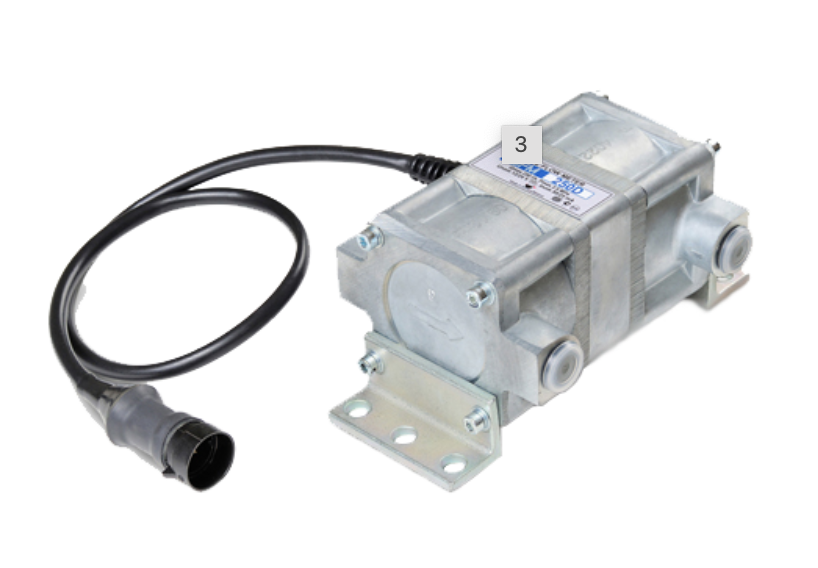

4. Type of Fuel Systems

In systems like “Common Rail” or “Unit Injector,” changes aren’t allowed. In these cases, DFM D differential flow meters are ideal for measuring fuel in supply and return lines. For systems that allow fuel to circulate (recirculation), single-chamber digital fuel meters provide accurate monitoring.

5. Select the Measurement Principle

Choose the right measurement method for your application. Common types include:

- Volumetric flow meter (e.g., turbine or positive displacement)

- Thermal mass flow meters for direct mass measurement

- Vortex flow meters for versatile industrial use

Each method calculates flow rate differently. Make sure the chosen principle aligns with your system’s needs.

6. Assess Environmental and Operating Conditions

Check if the flow meter can handle your system’s temperature, pressure, and any corrosive elements. For example, our partner uses duralumin to build DFM meter bodies. For marine environments, we recommend brass-bodied models to resist saltwater corrosion.

7. Determine Installation Requirements

Consider the cross-sectional area of your piping and available space. Check whether the meter supports your pipe’s orientation (horizontal or vertical). Make sure you have all required fittings or accessories for proper installation.

8. Evaluate Output and Communication Options

Select meters based on how you want to access or send data. Output options include:

- Analog: 4–20 mA for general integration

- Digital: RS-232, RS-485, Modbus, CAN J1939/S6, S7 (Bluetooth), NMEA 2000

If you’re connecting the meter to a vehicle tracking system, be sure to choose a DFM model with a compatible interface.

9. Consider Calibration and Maintenance

Check if the meter needs regular calibration for precise measurement. Some models offer easy access for servicing. Ask whether spare parts are available and affordable. Maintenance ease is key in choosing the right model.

10. Review Manufacturer’s Reputation and Support

Look into the manufacturer’s reliability, reviews, and technical support. At Metromatics, we offer local service, installation support, and guidance to help you make the best choice for your setup.

11. Compare Costs and Make a Decision

Compare models not just on price but on value, long-term reliability, and budget-friendliness. Consider the total cost of ownership, including installation, servicing, and calibration.

Metromatics Can Help You Choose the Right Fuel Flow Meter

We supply a wide range of DFM (Digital Fuel Meter) models. That measure liquids like diesel, petrol, biodiesel, and more. These meters suit cars, trucks, buses, marine vessels, and industrial machines.

DFM models offer:

- Single or dual measurement chambers

- Options for low and high flow rates

- Digital displays for real-time fuel analysis

- Wireless versions

- Models that connect to vehicle tracking systems

Fuel Flow Rate and Accuracy with DFM Flow Meters

Flow Rate Range:

DFM meters can measure a wide amount of fluid. From as low as 5 litres/hour up to 400 litres/minute. Depending on the model’s volumetric flow rate capabilities.

Accuracy:

Typical measurement accuracy is within ±1% of the measured fuel value.

Fluid Compatibility

DFM meters are compatible with many fuel types, including:

- Diesel, petrol, biodiesel, aviation fuel, kerosene

- Lubricants and hydraulic oils

- Coolants, ethanol blends, AdBlue/DEF, and chemical solutions

Check each model for temperature and viscosity limitations.

Measurement Principles Used

Our range includes:

- Turbine-based meters for standard applications

- Positive displacement meters like the DFM Marine for high-precision marine use

- Ultrasonic fuel flow meters (e.g., DUT-E 2Bio ULTRASONIC) for non-intrusive flow velocity measurement and calculated flow rate

Communication and Integration

We support various communication methods:

- Analog (4–20 mA)

- RS-232: Standard serial communication

- RS-485: Multi-device connection

- Modbus protocol: Popular in automation systems

- CAN: Widely used in automotive and industrial applications

- Wireless (Bluetooth or Wi-Fi) in select models

- Internal memory and built-in battery options available for standalone operation

- Some models require an external power source depending on usage

Always check your model’s communication options to ensure integration with your system.

Installation Accessories

Metromatics provides all necessary accessories, including:

- Mounting brackets and flanges

- Adaptors and connectors

- Wiring harnesses

- Seal kits

- Displays and controllers

- Calibration tools

Calibration and Servicing

Periodic fuel flow meter calibration ensures accuracy. Calibration compares the meter’s output with a known standard and corrects any deviation.

Calibration frequency depends on:

- The model

- Application demands

- Industry regulations

Local Support in Australia

Metromatics offers local sales, support, and installation services for all DFM fuel flow meters. Our knowledgeable team can help you choose the best model for your system and keep it running at peak performance.

Contact us today to get started with the right solution for your fuel monitoring needs.