As a control engineer, you are responsible for designing and implementing PLC control systems that are reliable, efficient, and cost-effective. Why not revamp your PLC with Acromag I/O ?

One critical component of any control system is the input/output (I/O) modules.

These components connect the control system to the sensors, actuators, and other devices that are used in the process.

If you are considering expanding your current PLC system, it is important to choose the right I/O modules to ensure that the system functions as intended.

In this blog, we will discuss why you should consider Acromag I/O products for this purpose. We will discuss the following:

- Benefits of expanding your PLC system

- Advantages of using Acromag I/O products

- The range of products available

- Key features of Acromag I/O products.

Our goal is to help you make an informed decision about choosing the right I/O modules for your control system, and to highlight why Acromag is a reliable and efficient option for your PLC expansion needs.

What is a PLC?

A PLC, also known as a Programmable Logic Controller, is a type of industrial control system. Used to automate and control various industrial processes and machines. It is a specialised computer designed to monitor inputs from sensors, process data, and control outputs to actuators in real-time.

Where is a PLC used?

PLCs are used in a variety of industries. Including manufacturing, automotive, food and beverage, and chemical processing, amongst others. They control processes in assembly lines, conveyor belts, and industrial machinery. In addition, they monitor and control environmental factors like temperature and pressure.

Why you would need to upgrade your PLC System and the benefits of doing so:

- Obsolescence – as technology advances, older PLC systems may no longer be supported by manufacturers. Or they may become incompatible with newer hardware and software. Therefore, ensuring compatibility with new technologies and provide better performance and functionality.

- Improve Efficiency and Productivity – newer systems have faster processing speeds, better memory and storage capacity, and improved communication capabilities. This can lead to reduced downtime, faster trouble shooting and repair times, and increased overall productivity.

- Comply with changing Industry Standards and Regulations – newer systems have better security features or improved safety features. These may be required to meet industry standards and ensure compliance with regulatory agencies.

- Increase Control and Automation – firstly, by adding more I/O modules, you can increase your control over the processes. Therefore, allowing for greater automation and more precise monitoring.

- Greater Insight to the Process – additionally, expanding your PLC system can allow you to add more sensors and devices. Therefore, improve your data collection and give you greater insights into the process.

Ultimately, the benefits of expanding your PLC system include improved control, meeting regulations, greater efficiency, and better data collection, all of which can contribute to a more profitable and streamlined operation.

So why revamp your PLC with Acromag I/O products?

Acromag offers a wide range of I/O modules. Including analog input and output modules, digital input and output modules, temperature and process control modules, and Ethernet-based modules for remote I/O applications. This variety of modules means that Acromag has a solution for almost any application. Making it a versatile choice for those looking to expand their PLC system.

Another advantage of using Acromag I/O products is their high quality and durability. Designed for use in harsh industrial environments. Modules are built to withstand extreme temperatures, vibration, and electrical noise. This means that they can operate reliably even in the most challenging conditions. Therefore, making them a dependable choice for critical processes.

In addition to their durability, Acromag I/O products also offer flexible communication options. Providing an easy integration with different PLC brands and protocols. Some examples of PLC brands they integrate with include: Allen-Bradley (Rockwell Automation), Siemens, ABB, Schneider Electric, Mitsubishi Electric, Omron, Beckhoff and more. This means that they can be easily incorporated into existing PLC systems. Therefore, reducing the need for complex configuration and ensuring compatibility with existing infrastructure.

Furthermore, Acromag provides user friendly software tools for configuration, monitoring, and troubleshooting. Making it easier to set up and maintain the system over time.

Overview on types of products available from Acromag

Acromag offers a wide range of input/output (I/O) modules. Designed to connect sensors, actuators, and other devices to programmable logic controllers (PLCs) and other automation systems. These modules can help to improve the efficiency and reliability of industrial processes by providing real-time data and control over various inputs and outputs.

Analog Input Modules

Analog input modules allow for the measurement and monitoring of voltage, current, and other analog signals from sensors and other devices. Therefore, providing real-time data on the state of the process being monitored.

Acromag’s analog input modules are available in a variety of configurations. This includes 2-channel, 4-channel, 8-channel, and 16-channel options. As well as a variety of input signal types and voltage/current ranges.

Example

913MB, 914MB: DC Current/Voltage Modbus-RTU Input Module with 4 input channels and limit alarms

924MB: Thermocouple/millivolt Modbus-RTU Input Module with 4 input channels and limit alarms

942MB: Frequency/Pulse Counter Modbus-RTU Input Modules with periodic or pulse waveform input.

963PB, 964PB: 12-channel single ended input Profibus-DP Modules

966PB: 4 or 6 channel RTD/Resistance Input Profibus-DP Modules

Other Analog Input Signal Conditioners and Network I/O Models

Analog Output Modules

Analog output modules allow for the control and regulation of analog signals to drive actuators and other devices. Therefore, providing precise control over the process being monitored.

Acromag’s analog output modules are also available in various configurations, including 4-channel and 8-channel options. Along with an array of output signal types and voltage/current ranges.

Example

917MB, 918MB: DC Current/Voltage Modbus-RTU Output Module with 4 Analog Output Channels and 4 Discrete Outputs for on/off control.

972PB, 973PB: 4 Channels of DC Current Analog Output or 6 Channels of DC Voltage Output

Digital Input Modules

Digital input modules allow for the monitoring of digital signals. Such as on/off signals from switches and sensors. They provide real-time data on the state of the process being monitored.

Acromag’s digital input modules are available in 8-channel and 16-channel configurations. As well as a range of input signal types and voltage/current ranges.

Example

901MB, 903MB: The 901MB is a Modbus-RTU Digital I/O with 12 discrete input channels. Whereas, Model 903MB is a Modbus-RTU Digital I/O with 12 discrete input or output channels.

981PB, 983PB: The 981PB is a Profibus-DP Digital I/O with 12 discrete input channels. Whereas, Model 983PB is a Profibus-DP Digital I/O with 12 discrete input or output channels.

Digital Output Modules

Digital output modules allow for the control of digital signals to drive relays, motors, and other devices. Therefore, providing precise control over the process being monitored.

Acromag’s digital output modules are also available in various configurations, including 8-channel and 16-channel options. Along with a series of output signal types and voltage/current ranges.

Example

902MB: The 902MB is a Modbus-RTU Digital I/O with 12 discrete output channels.

982PB: The 982PB is a Profibus-DP Digital I/O with 12 discrete output channels.

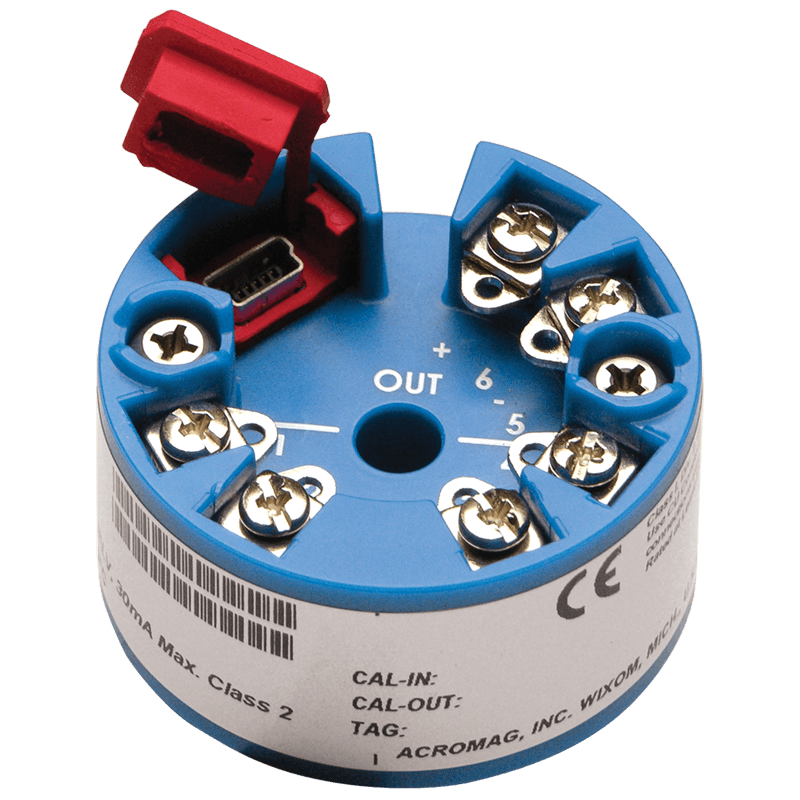

Temperature and Process Control Modules

Temperature and process control modules allow for the monitoring and control of temperature, pressure, and other process variables. In addition, providing real-time data and control over the process being monitored.

Acromag’s temperature and process control modules are available in various configurations. This includes single- and multi-channel options, with a range of input signal types and voltage/current ranges.

Example

TT334: Potentiometer / Thermistor 4 Wire Input changes resistive sensor input into 4-20mA Signal. DC Current & Voltage Output

ST131: Loop Power RTD Input Transmitter

DT233: 2 Wire dual transmitter with Thermocouple / mV Input converts to 4-20mA Signal

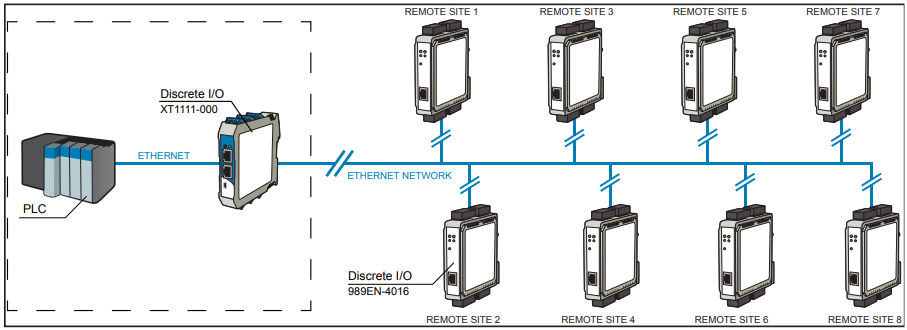

Ethernet-based Modules for Remote I/O applications

Ethernet-based modules for remote I/O applications allow for the integration of I/O modules into remote systems. Therefore, allowing for real-time data and control over the process being monitored from a central location. In addition, they are scalable, and you can add more as required. Also flexible, in terms of distance and placement which reduces wiring costs and provides better signal integrity.

These modules are available in a variety of configurations, with support for various Ethernet protocols and communication options. For example, ModBus, DeviceNET, Ethernet IP, PROFIBUS, EtherCAT, and CANopen.

NT2110: 16 bi-directional discrete channels Ethernet I/O Modules with NTX expansion models to add another 64 channels on a single IP address

XT1210: 8 Channel differential current input for Ethernet Network.

NT2620: Ethernet RTD Input Modules with 4 Resistance Input Channels and 2 Discrete I/O Channels. Ability to expand channels.

NT2610: Ethernet Temperature Input Modules with 8 thermocouple / millivolt inputs and 2 Discrete I/O Channels. Ability to expand Channels.

951EN, 952EN: Multi Function Ethernet or Modbus I/O Modules for analog and discrete I/O

Plus many more Ethernet I/O Modules to choose from.

Overall, Acromag’s range of I/O modules provides a versatile and reliable solution for a wide range of industrial automation applications.

Customisation of I/O Products

In addition, Acromag offers customisation options for their I/O products. So, this would allow control and process engineers to tailor the modules to their specific needs. Such as custom input/output ranges, custom labelling, and other modifications.

Acromag I/O offers key features to meet the needs of your PLC System

The wide range of I/O modules available from Acromag provides flexibility in selecting the appropriate modules for the specific application.

The high quality and durability of Acromag I/O products ensures reliable operation in challenging industrial environments, reducing downtime and increasing productivity.

Flexible communication options and easy-to-use software tools make it easy to integrate and maintain the I/O system, reducing the total cost of ownership.

Finally, customisation options allow for tailored solutions to meet specific needs. Overall, Acromag I/O products are a reliable and flexible solution for expanding PLC systems.

Conclusion

In conclusion, Acromag I/O products offer a wide range of modules with flexible communication options, high quality and durability, easy-to-use software tools, and customisation options.

Control engineers can benefit from these features when expanding their PLC systems, as it provides a reliable and flexible solution that meets the specific needs of their automation systems. With Acromag I/O products, control engineers can enhance their PLC systems with high-quality and reliable I/O modules, ultimately improving the performance and productivity of their industrial processes.

Metromatics provide local sales, service, and support for the Acromag product range to our customers in Australia and New Zealand. Contact us, so we can assist you with the upgrade to your PLC system.