AcroPack® is a modular, mezzanine-based embedded I/O platform from Acromag. Designed for compact, rugged, and long-life embedded systems. Firstly, it enables engineers to integrate high-density analog, digital, serial, and timing I/O. Whilst avoiding the size, rigidity, and redesign overhead of traditional PCIe I/O cards or remote Ethernet I/O.

By decoupling I/O from compute, AcroPack supports scalable architectures across industrial automation, transport, test and measurement, and defence electronics.

What Is Modular Embedded I/O?

Modular embedded I/O is an architecture. Where I/O functions are separate from the main compute platform. Instead of using fixed, monolithic I/O cards. Engineers select modular I/O building blocks that can be reused across different systems.

This approach improves:

- Design flexibility

- Platform reuse

- Upgrade paths

- Long-term lifecycle management

AcroPack is the implementation of this modular embedded I/O concept.

What Is AcroPack®?

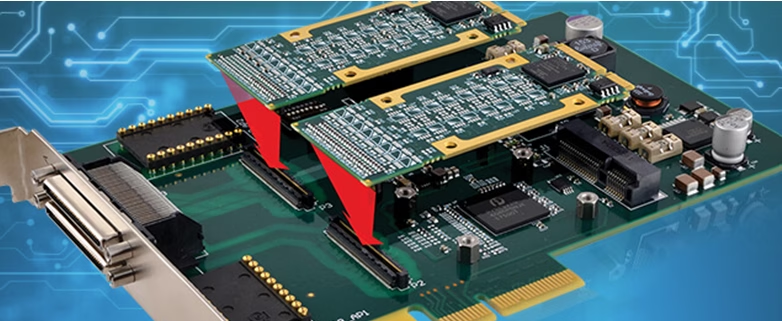

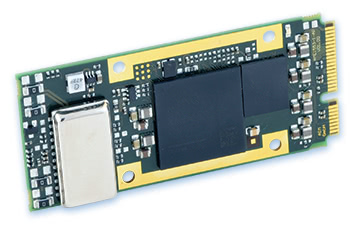

AcroPack modules are mini-PCIe-style mezzanine cards that plug into carrier boards. Each module delivers a specific I/O function. While the carrier interfaces those modules to the host system. Achieved by PCIe-based platforms such as PCIe, VPX, XMC, CompactPCI Serial, or COM Express.

This design allows engineers to:

- Select only the I/O required

- Combine multiple I/O types on one carrier

- Reuse the same I/O modules across multiple platforms

How the AcroPack Architecture Works

An AcroPack system consists of three core elements:

Host System

An embedded computer or processor card running the application software.

Carrier Board

A PCIe-based interface card that hosts one or more AcroPack modules and connects them to the host bus.

AcroPack I/O Modules

Compact mezzanine cards providing dedicated I/O functions.

Because the I/O remains modular, system upgrades often involve only a carrier change, reducing redesign risk and engineering cost.

AcroPack I/O Module Types

AcroPack supports a wide range of embedded I/O requirements:

Analog I/O Modules

High-resolution A/D and D/A channels for sensors, monitoring, and control loops.

Digital I/O Modules

Isolated and non-isolated inputs and outputs for discrete control and status signals.

Counter and Timer Modules

Event counting, pulse measurement, and timing applications.

Serial & Communication Modules

RS-232, RS-422, RS-485, Ethernet, and other industrial interfaces.

FPGA-Based Modules

Reconfigurable logic for custom protocols, deterministic processing, and specialised control tasks.

Why Modular Embedded I/O Matters

Traditional embedded I/O approaches introduce limitations:

- Fixed PCIe I/O cards are large and platform-specific

- Remote Ethernet I/O adds latency and network complexity

AcroPack addresses these challenges by providing:

- High I/O density in compact systems

- Deterministic, low-latency PCIe performance

- Reduced internal cabling and fewer failure points

- Easier upgrades across long program lifecycles

This makes modular embedded I/O particularly valuable in rugged and mission-critical systems.

Designed for Rugged and Long-Life Systems

Many AcroPack modules support wide operating temperature ranges and are suitable for conduction-cooled designs. This makes them well suited to:

- Defence and aerospace electronics

- Rail and transport systems

- Mining and industrial automation

- Scientific and research equipment

For long-life programs, modular I/O simplifies obsolescence management and future expansion.

Typical AcroPack Applications

AcroPack is commonly deployed in:

- Embedded control and monitoring systems

- Compact data acquisition platforms

- Platform-agnostic defence electronics

- Industrial test and measurement systems

Its modular design allows a single I/O strategy to scale across multiple platforms and deployment phases.

AcroPack vs Traditional Embedded I/O

| Approach | Limitation | AcroPack Advantage |

|---|---|---|

| Fixed PCIe I/O cards | Large, platform-specific | Compact, reusable mezzanine modules |

| Remote Ethernet I/O | Added latency and complexity | Direct PCIe-based access |

| Custom I/O designs | High cost and long development | Off-the-shelf modular I/O |

How Metromatics Supports AcroPack Integration

Metromatics provides local support across Australia and New Zealand, including:

- I/O module and carrier selection

- Embedded system integration guidance

- Support for industrial, transport, and defence programs

- Lifecycle and obsolescence planning

Frequently Asked Questions (FAQ)

What is AcroPack used for?

AcroPack is used to add modular embedded I/O—such as analog, digital, serial, and timing interfaces—to compact and rugged computing systems.

How is AcroPack different from PCIe I/O cards?

AcroPack uses mezzanine modules on carrier boards, allowing the same I/O to be reused across different platforms rather than locking I/O to a single PCIe card.

Is AcroPack suitable for defence and harsh environments?

Yes. Many AcroPack modules support wide temperature ranges and conduction-cooled designs, making them suitable for defence, transport, and industrial environments.

Can AcroPack be used across multiple platforms?

Yes. The same AcroPack I/O modules can be deployed on different carrier boards supporting PCIe, VPX, XMC, CompactPCI Serial, and COM Express architectures.

Does AcroPack support long-life programs?

Yes. Modular embedded I/O simplifies upgrades, reduces redesign effort, and helps manage obsolescence in long-term systems.

Summary

AcroPack® provides a scalable, rugged, and modular embedded I/O architecture that separates I/O from compute. This approach reduces system complexity, improves platform reuse, and supports long-life embedded programs across industrial, transport, and defence applications.

Talk to Metromatics about integrating AcroPack modular embedded I/O into your next embedded system.