This application note on Commercial Product Testing has been provided by our supplier FUTEK

Application Summary of Commercial Product Testing

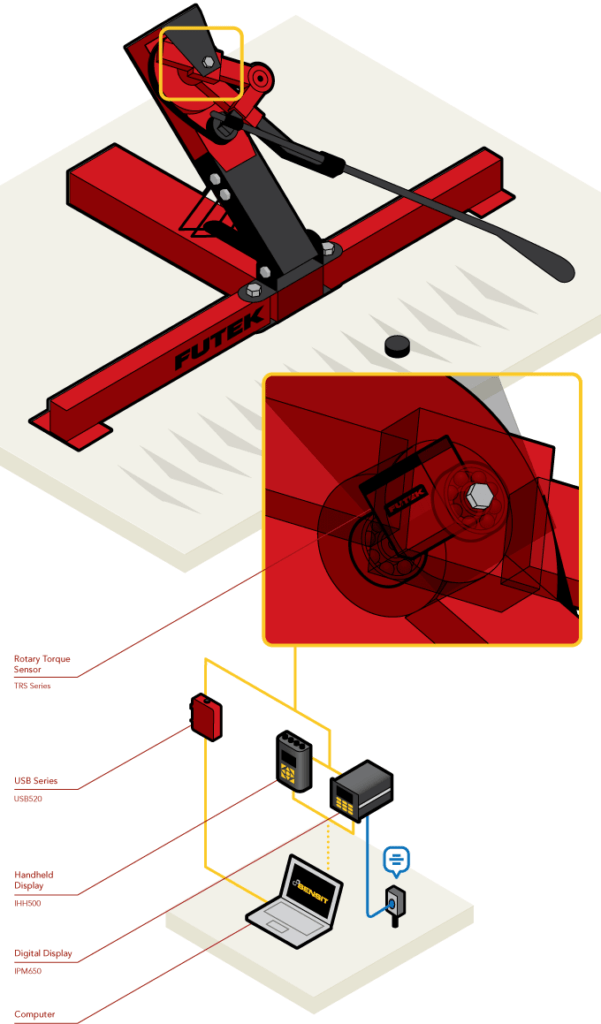

Due to safety regulations and consumer manufacturing standards, athletic equipment manufacturers often use Rotary Torque Sensors for commercial product testing.

Products in Use

Rotary Torque Sensor paired with Instrumentation (IHH500, IPM650, and USB520)

How it works

- The above application illustrates a commercial test stand for professional-grade hockey sticks.

- Utilising a Rotary Torque Sensor within the assembly of this robotic automation machine. Engineers can measure the breaking point – rotational force – of each slap shot.

- Whether to robotic arm winds to 180 degrees or to a full rotation of 360 degrees, the installed Rotary Torque Sensor will measure the exact torque exerted as the hockey stick strikes the puck.

- This data can be view on a digital display, such as FUTEK’s IHH500 Intelligent Digital Hand Held Display or IPM650 Panel Mount Display, or streamed directly to a PC via USB520.

- The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of industrial application.

- If the test engineers wish to collect, graph and interpret these results, they can apply FUTEK’s SENSIT™ Test and Measurement Software.

Please note all FUTEK Illustrations are purely conceptual.

Finally, for more information on this application, please contact us.