Why movement to an Automated Thoracic Retractor?

Firstly, opening a patient’s thoracic wall requires fast movement and consistent torque to minimise trauma. Secondly, this is accomplished with a hand cranked thoracic retractor operated by the surgeon. Using this methodology, current loops are typically applied in place of a torque sensor to monitor torque when automating small systems. However, this setup offers poor accuracy and a non-linearity of ± 5–10%. Therefore, FUTEK developed the Automated Thoracic Retractor.

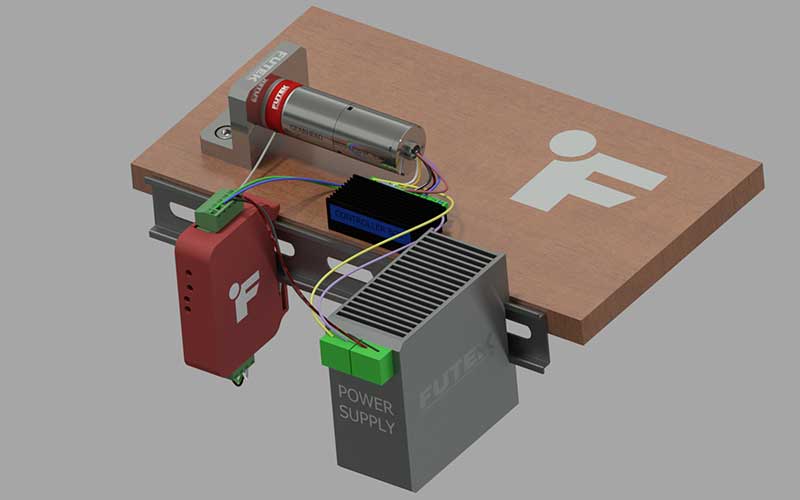

The QTA141, miniature servo motor, and gearhead with supporting electronics. FUTEK’s IAA series amplifier sends an amplified signal to the motor controller for closed loop control.

FUTEK have replaced the hand crank with the Automated Thoracic Retractor a miniature, high-precision, brushless DC servo motor and gearhead. Alongside the DC servo motor is FUTEK’s QTA141 Micro Reaction Torque Sensor, which has accuracy and non-linearity of ± 0.5%. Adopting this setup provides the surgeon with a faster and more accurate torque feedback system, in addition to benefiting the patient with less time spent in the operating room, a reduction in potential bone fractures, and a more rapid recovery time.

FUTEK’s QTA141 miniature torque sensor provides high accuracy, strain gauge, torque measurement in a 0.86″ diameter by 0.39″ height package.

QTA141 FEATURES

- 1 N-m Capacity

- 1.3 mV/V Output

- 0.86″ Diameter, 0.39″ Height

- 150% Safe Overload

- ± 0.5% of R.O. Nonlinearity and Hysteresis

- ± 0.2% of R.O. Nonrepeatability

This application note was kindly provided by our supplier FUTEK.

Finally, for more information, contact us.