Reliable power collection is fundamental to the safe and efficient operation of electric rail networks. At the heart of this process is the interaction between a train’s pantograph and the overhead catenary system. When this interface performs well, trains operate smoothly, efficiently, and safely. When it does not, rail operators face increased wear, power interruptions, safety risks, and unplanned maintenance.

Modern rail networks—particularly high-speed and high-voltage systems—require advanced testing and measurement techniques to understand and optimise this critical interaction. This article explains why pantograph and catenary testing matters. The challenges involved, and how modern data acquisition technologies are used to deliver reliable, standards-compliant rail operations.

This overview is based on a detailed technical article published by Dewesoft in collaboration with CETEST, a European railway test and analysis centre.

Why Pantograph–Catenary Interaction Matters

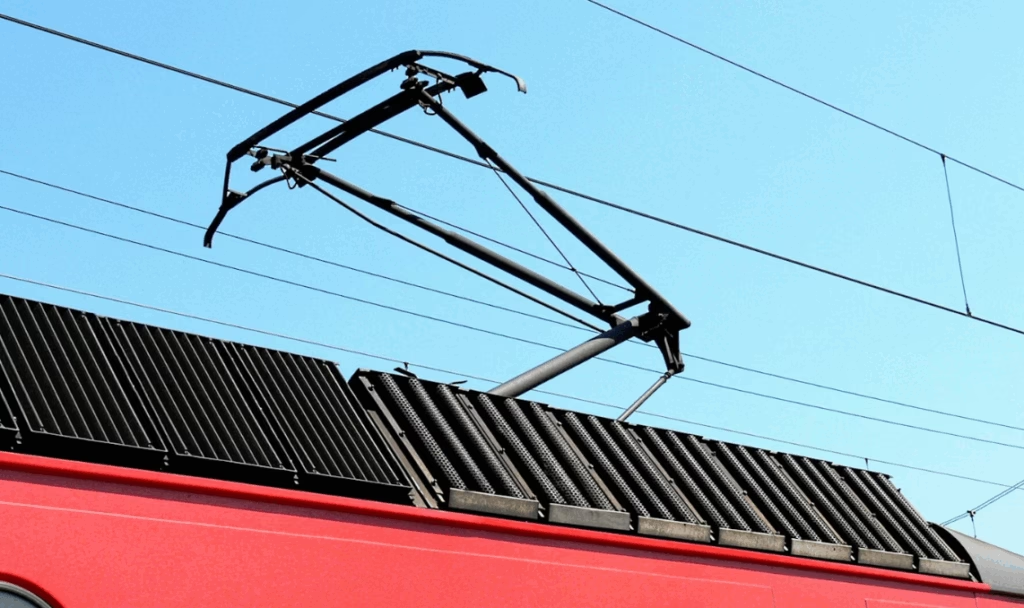

The pantograph is the roof-mounted mechanism that connects an electric train to the overhead contact wire. Typically operating at 15 kV or 25 kV AC. Its role is deceptively simple: maintain continuous electrical contact regardless of speed, weather, or track condition.

In practice, this interaction is one of the most demanding interfaces in rail engineering. Poor contact can cause electrical arcing and power loss. It can also lead to faster wear of pantograph carbon strips and contact wires. This issue may create electromagnetic interference and higher maintenance costs. It can result in service disruptions and safety risks, like dewirement or damage to overhead lines.

As train speeds increase and rail networks operate under tighter performance and safety requirements. Understanding the dynamic behaviour of the pantograph–catenary system becomes essential.

Testing Challenges in Real-World Rail Environments

Pantograph testing goes far beyond static measurement. Trains operate in highly dynamic environments characterised by high electromagnetic interference (EMI/RFI). In addition, vibration and aerodynamic forces at speed, variable wire heights, mechanical tolerances, and extreme weather conditions.

Instrumentation must function reliably in high-voltage environments, often mounted directly on the pantograph head, while delivering precise, synchronised data across multiple sensor types. For this reason, modern pantograph testing relies on multi-sensor, multi-physics measurement systems rather than single-parameter monitoring.

Key Measurements in Pantograph and Catenary Testing

Contact Force Measurement

Maintaining the correct vertical contact force between the pantograph and the overhead line is critical. Too little force causes contact loss and arcing; too much force accelerates mechanical wear. Force sensors provide real-time insight into contact behaviour and help validate force control mechanisms.

Vibration and Acceleration Analysis

Accelerometers measure vibration and acceleration across the pantograph head, revealing instability, excessive bouncing, or resonance effects that can compromise contact quality and structural integrity.

Displacement and Height Monitoring

Displacement measurements show how well the pantograph follows the catenary wire profile and ensure it remains within safe clearance limits under bridges and tunnels.

Thermal Monitoring with Infrared Cameras

Infrared cameras monitor temperature at the contact interface. Elevated temperatures can indicate excessive friction, arcing, or abnormal wear, enabling early fault detection without physical contact.

Arc Detection Using UV Sensors

UV arc sensors detect and quantify arcing events at the contact interface, supporting fault localisation and compliance with recognised testing standards.

Data Acquisition for Pantograph Testing

Modern pantograph testing requires high-resolution, synchronised data acquisition capable of combining mechanical, electrical, thermal, and positional measurements.

Dewesoft DAQ systems are widely used due to their modular design. As well as their electrical isolation, and ability to operate reliably in harsh rail environments. These systems can integrate analogue sensor inputs, cameras, GNSS for speed and position correlation. In addition, inertial measurement units (IMUs), and vehicle bus data such as CAN or MVB. Therefore, allowing all measurements to be synchronised and analysed in real time.

Standards in the Australian Rail Context

While Australia does not mandate EN 50317 or EN 50367 as national standards. However, they are widely referenced across Australian electrified rail projects. These standards are commonly adopted by rolling stock OEMs, infrastructure contractors, and test engineers as internationally recognised best practice for validating pantograph–catenary interaction.

In Australia, EN standards are typically used alongside local rail authority requirements and Australian Standards covering electrical safety and installation. Therefore, providing a robust framework for performance validation, acceptance testing, and ongoing monitoring.

From Field Testing to Analysis and Visualisation

Data collected during testing is analysed using DewesoftX software. Therefore, enabling engineers to replay test runs, validate measurement quality, perform detailed post-processing, and visualise data alongside video, maps, and sensor channels.

For long-term monitoring and remote access, cloud-based tools such as Dewesoft Historian allow engineers and asset managers to view data from anywhere, supporting condition-based maintenance strategies.

How Metromatics Supports Rail Testing in Australia & New Zealand

Metromatics is the Australian and New Zealand distributor for Dewesoft. We help rail operators, rolling stock manufacturers, and test engineers. Our support includes local technical advice, system setup guidance, and long-term application help.

We work closely with customers across passenger rail, light rail, and infrastructure projects. To ensure measurement systems are fit for purpose and aligned with international best practice.

Frequently Asked Questions

What is pantograph and catenary testing?

Pantograph and catenary testing evaluates the dynamic interaction between a train’s pantograph and the overhead contact line. Therefore, to ensure stable power collection, reduced wear, and safe rail operation.

Which standards are used for pantograph testing?

Testing commonly references internationally recognised standards such as EN 50317 and EN 50367, which define measurement methods and performance criteria for pantograph–catenary interaction.

What parameters are measured during pantograph testing?

Key parameters include contact force, vibration, displacement, arcing events, temperature, speed, and position.

Is pantograph testing relevant for Australian rail networks?

Yes. Pantograph testing is essential for electrified rail systems in Australia. In addition it is widely used during acceptance testing, performance validation, and ongoing monitoring.

What role does data acquisition play in pantograph testing?

Data acquisition systems synchronise multiple sensor inputs in real time, allowing engineers to analyse complex mechanical and electrical interactions under real operating conditions.

Talk to Metromatics

Metromatics supports rail operators, OEMs, and test engineers across Australia and New Zealand. With Dewesoft-based data acquisition solutions for pantograph, catenary, and rail infrastructure testing.

Contact our team to discuss your application or upcoming project.

👉 Read the original Dewesoft technical article here:

https://dewesoft.com/blog/pantograph-and-catenary-testing