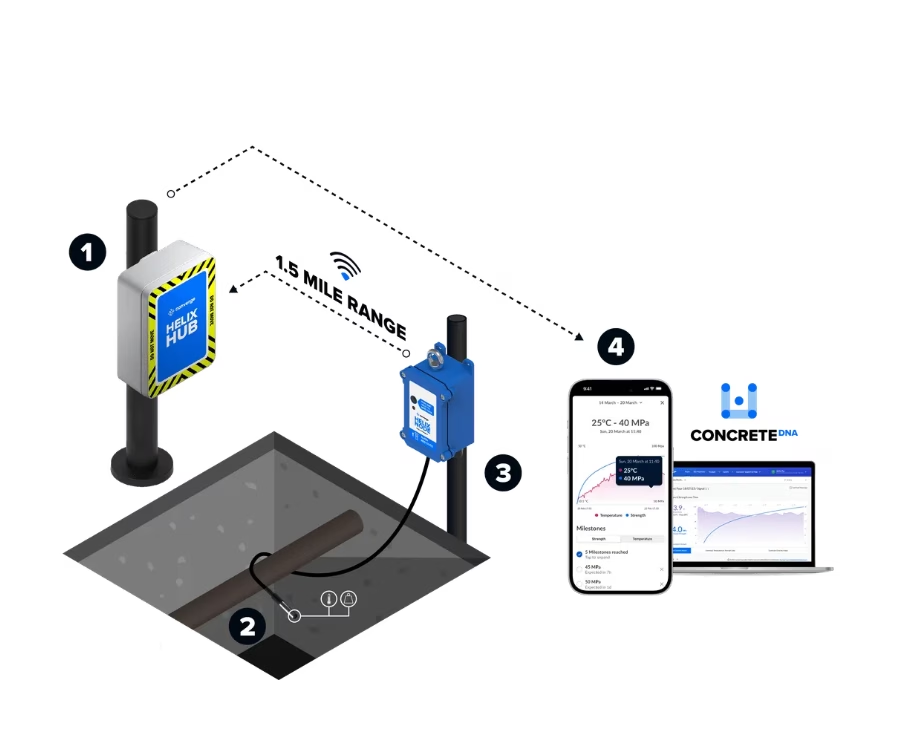

The Converge Helix® Long-Range System is a reusable concrete monitoring sensor. It’s the best choice for reliable, reusable concrete monitoring across your entire site. It is designed to grow with your needs. This system uses embedded probe tails and reusable Helix nodes. It captures internal temperature and strength data from large builds. Then, it wirelessly sends this data with great range and flexibility.

Key Features & Capabilities

Reusable design: Helix nodes detach and can be redeployed across multiple pours and projects. Therefore, lowering lifecycle cost and waste.

Embedded probe tails: Thermal Tails™ are cast into the concrete. They measure internal parameters and pass data to the Helix Node.

Long-range wireless comms: Helix supports communication over extended distances. Approximately 2.4 km in open terrain to cover large or complex job sites.

Hub & relay architecture: Data moves from the node to a Helix Hub. Then, it goes to the Converge cloud or ConcreteDNA® dashboard for live visibility.

Scalable network: You can use many nodes and hubs to build a mesh or network. This can work across formwork, structures, or terrain obstacles.

Robust construction: Built for harsh site conditions. Nodes are protected and easy to mount on formwork, hoarding, or temporary structures.

Precision measurement: The embedded tails capture internal temperature and strength development with calibration consistent with embedded sensor accuracy.

Cloud analytics & alerts: All data is streamed into the ConcreteDNA® platform. Providing trend graphs, predictive strength models, and automated alerts.

Benefits & Why Choose Helix

Cost-effective over multiple pours: Because nodes are reusable, the cost per use drops with every new project.

Greater reach across large sites: Ideal for infrastructure, bridges, tunnels, or dispersed pours. Where embedded-only systems can’t communicate.

Flexible deployment: Nodes can be repositioned, scaled, or networked to suit changing site layouts.

Improved safety & certainty: Continuous insight into internal concrete behaviour — reducing guesswork, cracking risk, and delay.

Sustainable option: Reusability reduces waste from sacrificial sensors and supports greener construction practices.

Typical Applications

Major civil structures: bridges, dams, tunnels

Mass concrete pours and thermal differential control

Long spans & complex formwork geometries

Large slabs, foundations, and distributed elements

Multi-pour projects where reuse is critical

Helix Node – Reusable Concrete Monitoring Sensor

A surface-mounted wireless transceiver (node) that receives data from Thermal Tails and relays it to the Helix Hub. The Node is reusable: once one pour is done, it can be detached from the tails and redeployed on another pour.

Technical Specifications

| Description | Long range sensor node |

|---|---|

| Device dimensions (LxWxH) | 133 x 66 x 47 mm |

| Weight | 206g |

| IP Rating | IP67 Waterproof |

| Operational Temperature range | -40 to 85°C |

| Enclosure materials | Shell material: ASA Button material TPU |

| Bluetooth version | v5.1 |

| LoRaWAN range | Up to 1.5 miles in open space |

| Measurement frequency | Every 20 mins |

| Battery chemistry and voltage | 3.6v Lithium Thionyl Chloride battery (Not replaceable) |

| Maximum recommended shelf life | 2 years |

| Internal battery capacity | 8500mAh |

| Internal battery voltage | 3.6v |

| Internal battery Wattage | 30.6wh |

| Applicable Products | ConcreteDNA |

Thermal Tails

These are the temperature/strength sensing probes cast into your concrete at pour time. They are available in single-probe or multi-probe variants, allowing measurement at multiple depths. Once embedded, they feed internal data to the Helix Node, enabling in-situ maturity and strength tracking. Available in 1 Metre, 5 Metre and 10 Metre lengths.

Helix Hub

The Hub aggregates data from one or more Nodes and uploads it to the cloud / ConcreteDNA® platform. It functions as the system’s gateway, ensuring critical insights reach your dashboard. With optimal placement, the Hub enhances network coverage and ensures consistent long-range connectivity across the job site.

Integrated Software and App Support

All Converge wireless sensors — including the Helix® Reusable Concrete Monitoring System — connect seamlessly with the Converge mobile app and ConcreteDNA® web platform to deliver complete digital concrete visibility.

Mobile App (Bluetooth) – Used to register Helix Nodes and Thermal Tails, check live readings, and verify connectivity during setup. The app also allows users to view local data or manually trigger syncs if required.

ConcreteDNA® Cloud Platform – Receives live data automatically from the Helix Hub. Displaying temperature and strength graphs, historical trends, and maturity-based strength predictions.

Mix AI™ and Cure™ Modules – Optional analytics tools within the Converge ecosystem. That use predictive algorithms and historical data to optimise mix performance, curing cycles, and sustainability outcomes.

These systems provide a full wireless concrete monitoring solution. This includes on-site installation, registration, real-time data analysis, AI predictions, and performance checks.

How It Works

Helix Hub: Set up and install the Helix hub in a central and elevated position with good visibility. The Helix System can now send the data to ConcreteDNA

Thermal Tail: Connect a Thermal Tail to the Helix Node. Register the tail using the Concrete DNA mobile app simply by scanning the QR code. Attach the probe to the rebar at your desired measurement point. The embedded probe will send temperature and strength data to the node.

Helix Node: Turn on the Helix Node. Attach it to hoarding or an elevated position outside the pour. It will transmit data to the Hub and onto ConcreteDNA. Once monitoring of the pour is complete, simply detach the Node from the Tail and reattach to the new desired tail.

ConcreteDNA: Use the ConcreteDNA app to manually collect data over bluetooth from Helix Node. View concrete strength, temperature, and AI milestone predictions in real time.

Metromatics provides local sales and support for wireless concrete sensor systems in Australia.

Our engineers can help you choose the right mix of Sensors, Thermal Tails and Hubs for your project. This will ensure full compatibility with Converge’s ConcreteDNA® platform.

Contact us today to discuss your project or request a demonstration.

Prefer a single-use solution instead? Learn more about the Converge Signal® Embedded Concrete Sensor for reliable, fully embedded wireless monitoring. Or for a large pour the Converge Long Range Wireless Embedded Concrete Sensor.