The development of new rocket propellants depends heavily on accurate, repeatable ground testing. Before any propulsion system progresses to flight qualification, engineers must fully understand how a propellant behaves under controlled conditions. Particularly thrust output, chamber pressure, burn rate, and thermal performance.

Rocket motor static testing provides this critical insight. Firstly by testing a motor during a static firing, propulsion engineers can check propellant formulas. In addition, they can confirm performance models and spot potential risks early in development. This article explores why static testing is essential. Such as the challenges involved, and how modern data acquisition systems support high-fidelity propulsion testing.

This overview is informed by a detailed technical article published by Dewesoft, focusing on real-world rocket motor static testing for propellant development.

Why Static Testing Matters in Propellant Development

Propellant behaviour cannot be fully characterised through simulation alone. Factors such as combustion stability, pressure oscillations, ignition transients, and structural loading must be measured directly under firing conditions.

Static firing tests allow engineers to:

- validate thrust and pressure profiles

- assess burn consistency and efficiency

- evaluate structural loads on motor casings and test stands

- confirm thermal behaviour during sustained combustion

- correlate empirical data with simulation models

For space launch systems, defence applications, and experimental propulsion programs, this data is essential for reducing development risk and accelerating qualification timelines.

Challenges of Rocket Motor Static Firing Tests

Static testing of rocket motors presents unique measurement and safety challenges. Tests involve extreme temperatures, high pressures, rapid transients, and highly energetic events occurring over short timeframes.

Key challenges include:

- capturing high-speed pressure and thrust transients

- maintaining signal integrity in electrically noisy environments

- synchronising multiple sensor types during ignition and burn

- protecting instrumentation from heat, vibration, and shock

- ensuring reliable data capture during one-off or limited tests

These challenges demand robust instrumentation, precise timing, and highly reliable data acquisition architectures.

Key Measurements During Static Rocket Motor Tests

Thrust Measurement

Load cells are used to measure thrust output throughout the firing sequence. Accurate thrust data enables engineers to validate propulsion performance, efficiency, and total impulse against design expectations.

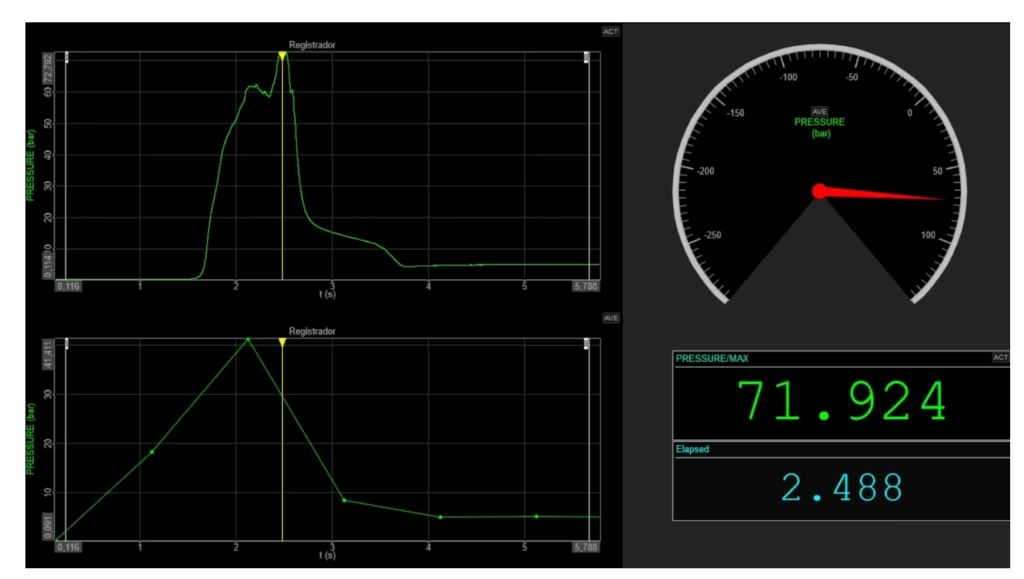

Chamber Pressure Monitoring

High-speed pressure transducers capture combustion dynamics within the motor. Pressure data is critical for assessing burn stability, identifying oscillations, and validating propellant grain geometry.

Temperature and Thermal Behaviour

Thermocouples or non-contact temperature sensors monitor motor casing and exhaust conditions. Thermal data supports material selection, insulation design, and safety analysis.

Vibration and Structural Response

Accelerometers measure vibration and shock transmitted through the motor and test stand. This data helps engineers understand structural loads and potential failure modes during ignition and burnout.

Event Timing and Synchronisation

Precise time alignment between ignition, pressure rise, thrust generation, and shutdown is essential for accurate analysis and repeatable testing.

Data Acquisition for Rocket Propulsion Testing

Modern rocket motor testing relies on high-speed, synchronised data acquisition capable of handling multiple sensor types with deterministic timing.

Dewesoft data acquisition systems are commonly used in propulsion testing due to their ability to:

- sample high-speed analogue signals with high resolution

- synchronise pressure, force, temperature, and vibration channels

- capture transient events without data loss

- operate reliably in harsh, high-energy test environments

By integrating all measurements into a single time-aligned dataset, engineers can analyse complex interactions between propellant behaviour, mechanical loads, and thermal effects.

From Test Data to Insight

Post-test analysis is as important as the firing itself. Data replay and validation using Dewesoft X Software allow engineers to:

Post-test analysis plays a critical role in propulsion development—just as important as the firing itself. Using DewesoftX software, engineers actively replay and validate test data to:

- verify sensor performance

- quickly identify anomalies or unexpected behaviour

- correlate measured data with simulation models

- refine propellant formulations and motor designs

As a result, advanced analysis tools help teams extract maximum value from every static test. Which is especially important when test opportunities are limited, complex, or costly.

How Metromatics Supports Propulsion Testing in Australia & New Zealand

Metromatics is the Australian and New Zealand distributor for Dewesoft, supporting aerospace organisations, research institutions, and defence programs involved in propulsion testing.

Specifically, we help customers by providing:

- guidance on system selection and configuration

- support for sensor and instrumentation integration

- assistance with static test stands and experimental setups

- long-term technical support across the full test lifecycle

Ultimately, our focus is to help teams capture reliable, high-quality data that accelerates development timelines while reducing technical and test risk.

Frequently Asked Questions

What is a rocket motor static firing test?

A static firing test involves securing a rocket motor to a test stand and firing it under controlled conditions. For instance, to measure thrust, pressure, temperature, and structural response without flight.

Why is static testing important for propellant development?

Static testing provides real-world data on combustion behaviour, performance, and stability. That cannot be fully captured through simulation alone.

Parameters that are typically measured during a static test?

Firstly, common measurements include thrust, chamber pressure, temperature, vibration, and event timing.

Is static rocket motor testing relevant in Australia?

Yes. Static testing is used by Australian defence programs, space launch initiatives, research institutions, and university propulsion teams.

What role does data acquisition play in propulsion testing?

Data acquisition systems synchronise and record all sensor inputs during a firing event, enabling accurate analysis of complex, high-speed phenomena.

Talk to Metromatics

Metromatics supports propulsion engineers, test facilities, and aerospace programs across Australia and New Zealand. With Dewesoft-based data acquisition solutions for rocket motor static testing and experimental propulsion development.

Contact our team to discuss your testing requirements.

👉 Read the original Dewesoft technical article here:

https://dewesoft.com/blog/propellant-development-rocket-motor-static-test