As industrial automation evolves, more organisations are looking for ways to integrate field data directly into software systems, cloud platforms, and IIoT architectures. This shift has created growing interest in a new class of devices known as REST API I/O Modules.

But what exactly does this term mean?

Why is it becoming so important?

And how does it benefit engineers, integrators, and automation designers?

In this guide, we break down everything you need to know.

What Is a REST API I/O Module?

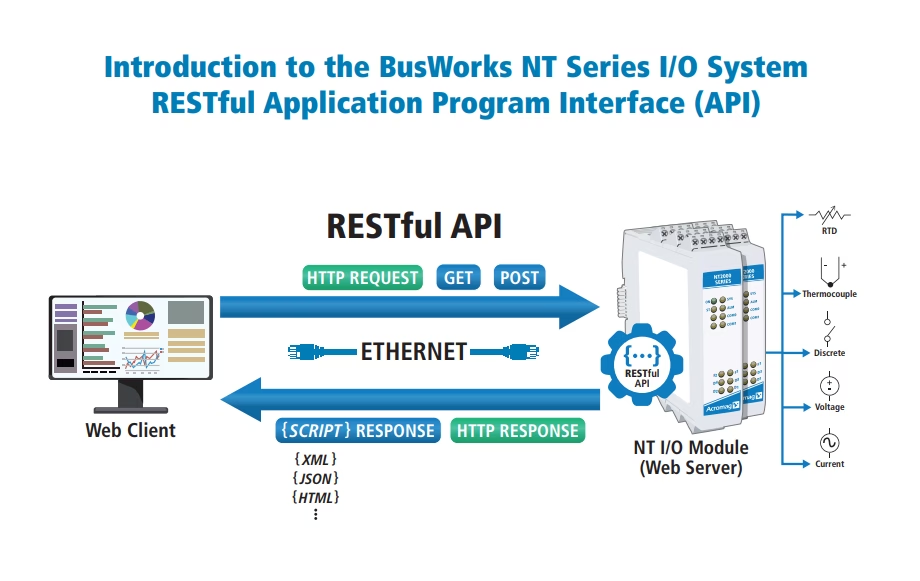

A REST API I/O Module is an industrial input/output device that can be read or controlled using standard web commands. Such as HTTP GET and HTTP POST.

A REST API I/O module shares its data using a web-based interface. This interface is called a RESTful API. It is different from traditional industrial protocols like Modbus TCP, EtherNet/IP, and PROFINET.

This means you can:

- Read digital or analog inputs

- Write digital or analog outputs

- Retrieve configuration information

- Control device behaviour

- Pull live sensor values

- Integrate directly with web, cloud, or custom applications

All using simple HTTP commands — the same language used by web browsers, mobile apps, and cloud services.

Why REST Matters in Industrial I/O

REST (Representational State Transfer) is the most widely used communication architecture on the internet.

When applied to industrial I/O devices, REST offers several major benefits:

1. Universal Compatibility

Any system that can send an HTTP request can interact with a REST-enabled I/O module.

This includes:

- Python scripts

- JavaScript web apps

- SCADA systems

- ERP integrations

- Cloud dashboards

- Mobile applications

- Edge devices

- IIoT gateways

No proprietary tools or vendor-specific drivers required.

2. Easy to Use for Developers

REST APIs are developer-friendly:

- HTTP GET → retrieve data

- HTTP POST → send data/commands

- JSON/XML → structured machine-readable output

This makes integration far simpler than traditional PLC-based interfaces.

3. Ideal for IIoT & Cloud Projects

REST API I/O modules can:

- Stream data to cloud platforms

- Connect to dashboards like Grafana

- Integrate with AWS, Azure, Google Cloud

- Feed analytics or machine-learning systems

- Enable remote monitoring and diagnostics

REST becomes the bridge between field equipment and modern software ecosystems.

4. Lower Integration Cost

REST eliminates:

- Middleware

- Custom drivers

- Proprietary communication stacks

- Complex PLC programming for basic tasks

This reduces development time, maintenance demands, and system complexity.

5. Perfect for Distributed, Remote, or Smart Infrastructure

REST-enabled I/O is ideal for:

- Transport systems

- Water and wastewater networks

- Energy monitoring

- Industrial edge computing

- Building automation

- Defence data acquisition

- Smart-city infrastructure

- Environmental monitoring

- Remote pumping stations

These systems increasingly require direct software-driven access to live field data across wide networks — something REST is perfectly suited for.

How a REST API I/O Module Works

A REST-enabled I/O module typically provides:

- A network interface (Ethernet or Wi-Fi)

- A built-in web server

- A RESTful API endpoint

- Input/output channels (analog, digital, RTD, thermocouple, etc.)

Example: Reading a Channel Value

GET http://device-ip/webif/slots/1/analog-input/3

Example: Setting a Digital Output

POST http://device-ip/webif/slots/0/digital-output/1

value=1

This simplicity makes automation scripting extremely powerful and accessible.

⭐ How REST API I/O Compares to Traditional Protocols

| Feature | REST API | Modbus TCP / EtherNet/IP |

|---|---|---|

| Human-readable | Yes | No |

| Works with any web tool | Yes | No |

| Developer-friendly | Yes | Medium |

| Cloud-ready | Excellent | Limited |

| Requires PLC | No | Often yes |

| Uses HTTP | Yes | No |

| Flexible for custom apps | Very high | Medium |

Both approaches have value — but REST is ideal for modern software-led automation.

⭐ Example: Acromag NT Series RESTful API

A leading example of this modern approach is the Acromag BusWorks NT Series. They include a fully integrated RESTful API for monitoring and controlling I/O channels over Ethernet.

Acromag’s white paper provides detailed guidance on how developers can:

- Authenticate

- Retrieve slot information

- Read analog and digital channels

- Modify outputs

- Send structured HTTP requests

You can view the full white paper here:

📄 Acromag – Introduction to the BusWorks NT Series RESTful API

With this upgrade, the NT Series becomes a powerful choice for integrators designing modern IIoT, smart infrastructure, and distributed automation systems.

Why REST API I/O Modules Are the Future

As OT and IT converge, REST is quickly becoming a preferred method for:

- Simplifying automation architectures

- Bridging field devices with enterprise software

- Making I/O accessible to analytics and cloud systems

- Reducing lifecycle cost

- Enabling scalable remote monitoring

- Supporting digital transformation initiatives

REST API I/O Modules align perfectly with Industry 4.0, edge computing, and cloud-native automation strategies.

Conclusion

A REST API I/O module represents a major step forward in industrial automation.

By combining field reliability with web-based communication, it enables faster integration, smarter systems, and broader connectivity than traditional I/O modules.

As the industry embraces IIoT and software-driven automation, REST-enabled devices like the Acromag NT Series will become increasingly essential for engineers who want flexible, future-proof solutions.

Want more information? Contact Metromatics.