This blog on the Structural Health Monitoring of Buildings was originally supplied by our friends at Dewesoft Italia. To read the original article, click here. It is on the preserving of a historical and monumental building called the Opera del Duomo d’Orvieto written by support engineer, Alessia Longo.

Summary of Structural Health Monitoring of Buildings

Firstly, Italy is known for its amazing history, buildings and monuments that have stood for centuries. It is important to preserve this heritage. One method of preservation that is used is called structural monitoring. Structural monitoring does not distort the authenticity of the buildings but provides diagnostic information and monitoring and reports this information to relevant stakeholders.

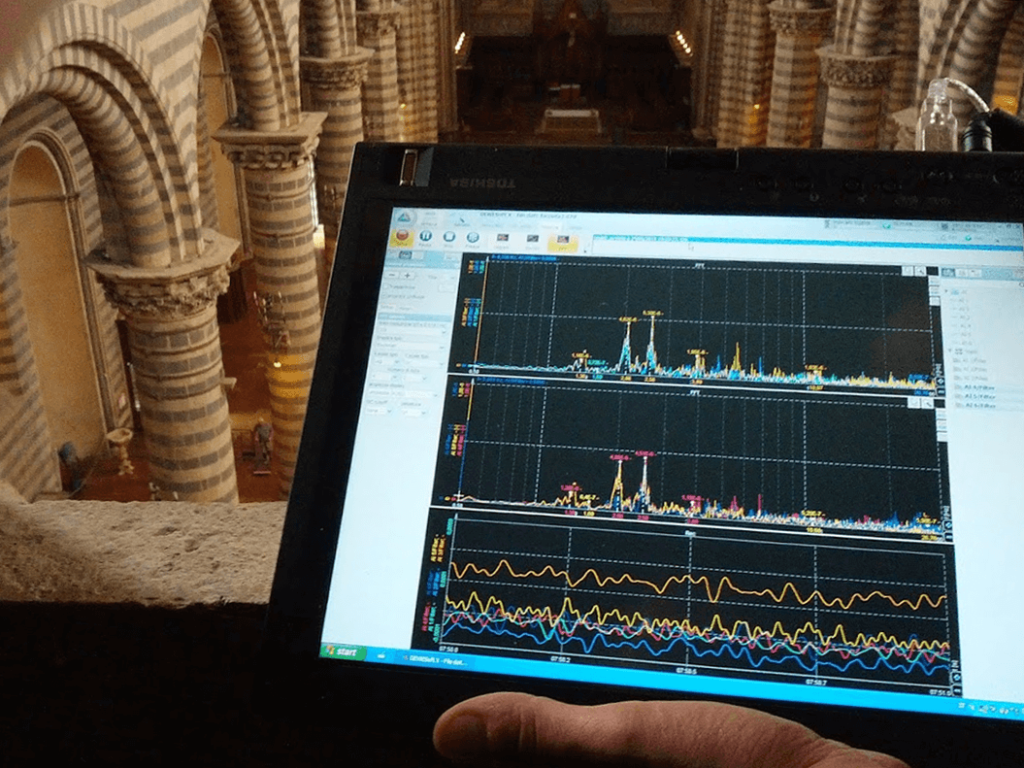

Therefore, Dewesoft have installed a permanent dynamic monitoring system into one of the master pieces of Gothic Architecture in central Italy: the Cathedral of Orvieto.

About the Cathedral of Orvieto

The Cathedral of Orvieto is also known as the Basilica of Santa Maria Assunta. Located in the city of Orvieto in Central Italy. It was originally constructed in 1290 AD. It features numerous architectural styles including Gothic and is quite magnificent.

Opera del Duomo d’Orvieto is responsible for maintaining the Cathedral, administering its assets, conserving works of art and managing the museum. This autonomous body decision to install a permanent health monitoring system at the Orvieto Cathedral in collaboration with Dewesoft. The town is one of the most earthquake active areas in Italy. It is often struck by a strong motion earthquake at least once a decade. The Orvieto underground has several fault lines and active seismic structures.

The Monitoring Instrumentation Setup

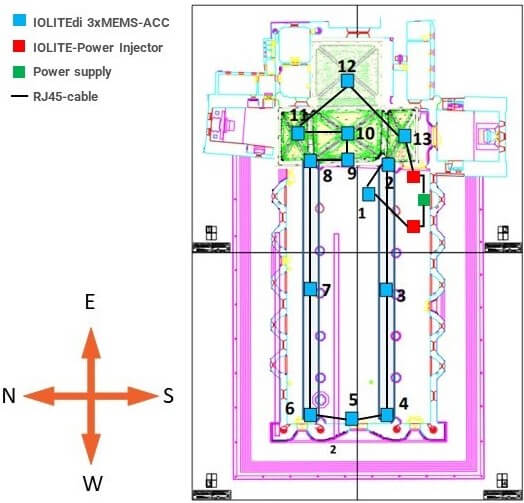

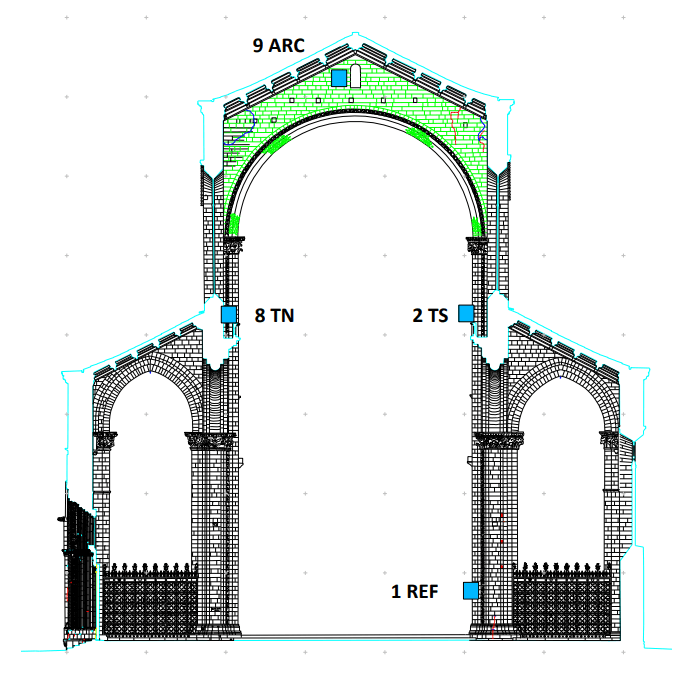

The structural health monitoring system was installed to evaluation the dynamic interaction of the macrostructural elements of the cathedral. Including the transept, nave, and façade.

Also, amplifications from the accelerometric signal at different points of the cathedral are monitored over time. They reflect the responses of the structure. Following stresses due to seismic activity, daily traffic or construction works in the surrounding areas. All these responses can modify the structure resulting in structural degradation.

Works were about to be undertaken in the coming months to make the Basilica and its façade into a single coherent structure. So, this measurement installation enables crucial monitoring.

The products used

The Dewesoft IOLITEi-3xMEMS is an acquisition module with built in sensor. Acceleration is measured with inbuilt triaxial MEMS accelerometer. It was perfect for the application.

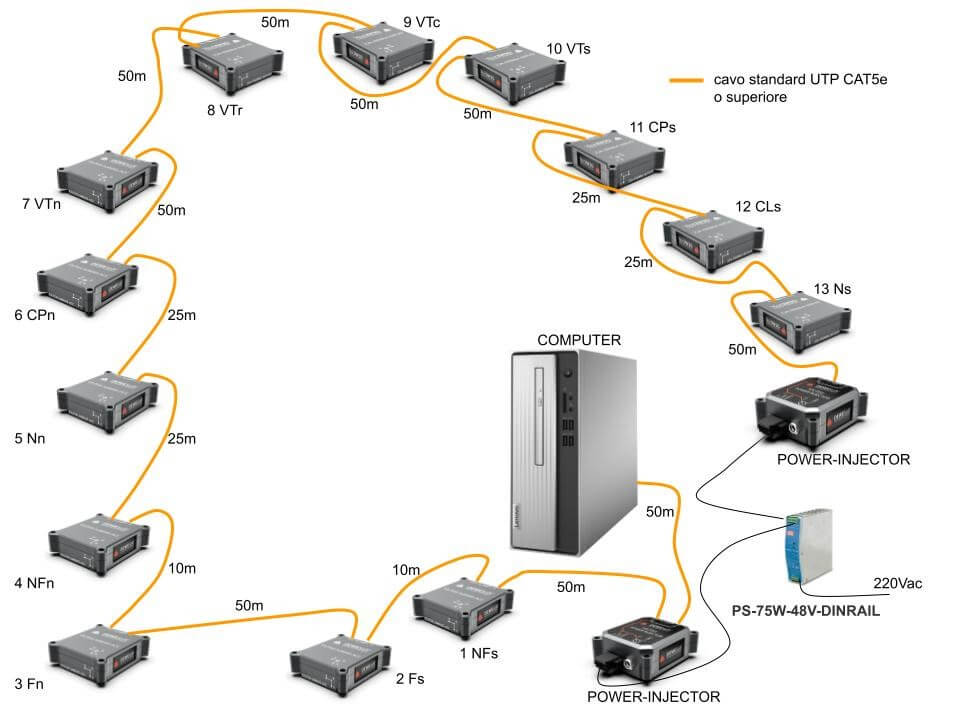

Hardware configuration is a closed loop. Modules are place in an EtherCAT measurement chain. With several nodes distributed at strategic points of the structure. Therefore, 13 x IOLITE devices were installed along columns, nave and on central vault.

Also, two IOLITE power injector modules were installed. This PoE technology provided power to two branches of the ring from a single point with a single power source. This was because the electrical network of the building structure was not capable of powering the acquisition chain path.

Communication is via EtherCAT protocol which allows the distribution of IOLITE devices on large structures. It can communicate 50 Metres node to node. Connection is by single network cable for signal, power and data synchronisation. Greater distances can be covered by using a passive repeater between two measurement points. Also, the system can easily be expanded with more accelerometers should it become necessary.

The Measurements

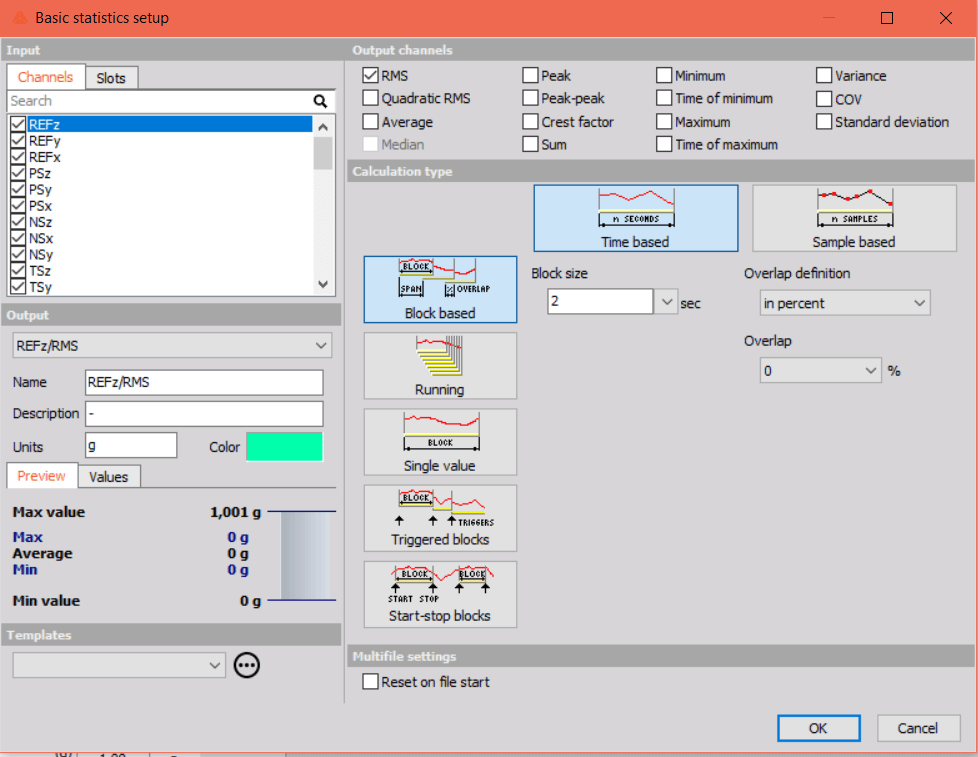

Configuration of the setup was straightforward and immediate. The modules are automatically recognised by the DewesoftX Software. The user is left with simple choice of the most suitable unit of measurement. In this particular case, data is acquired with a sampling frequency of 100 Hz recording only the raw data and maximum RMS scalar values of the triaxial accelerometers.

During the acquisition phase, the instant RMS value of each channel is calculated using basic statistical maths is displayed to detect an anomalies.

Software can be configured for remote use. The acquisition system can be put online, and users can view data without being on the site. Monitoring is done from an office in Rome due to the unstable internet network.

The system will record 24 hours with the option to have multiple data files each lasting 1 hour. In post processing, this option provides to merge all the files together for a complete overview or single data file for each one-hour section.

The DewesoftX software provides the opportunity to record data on an event or trigger basis. This reduces the amount of data a structure expert will need to analyse. Alarms and sending of email notifications when an event occurs.

IOLITEi-3xMEMS: The DAQ Device with integrated accelerometer sensor

Firstly, the IOLITEi-3xMEMS acquires data through its integrated sensor. The A/D conversion of the signal is done within the instrument. It eliminates noise problems.

Secondly, the integrated microprocessor transmits the sampled acceleration values to the Dewesoft X Software installed on a PC or sends data to an EtherCAT master on the preferred platform. Automatic scaling of data means it is immediately available in g or m/s.

Thirdly, a built-in temperature sensor measures the atmosphere temperature in which the accelerometer is subjected. Values updated every second.

The IOLITEi-3xMEMS modules are the optimal basis for structural integrity or permanent monitoring solutions in civil engineering structures such as bridges, pylons, antennas, buildings and stadiums. Excellent economical alternative for seismic monitoring.

Conclusion on the Structural Health Monitoring of Buildings

Finally, respecting and preservice historical heritage over the years is important. To do so it is necessary to resort to diagnostic and prevention solutions capable of not distorting their authenticity and beauty. Dewesoft are fully in line with this philosophy. They allow continuous monitoring of the structures and the same time ensuring a non-destructive analysis