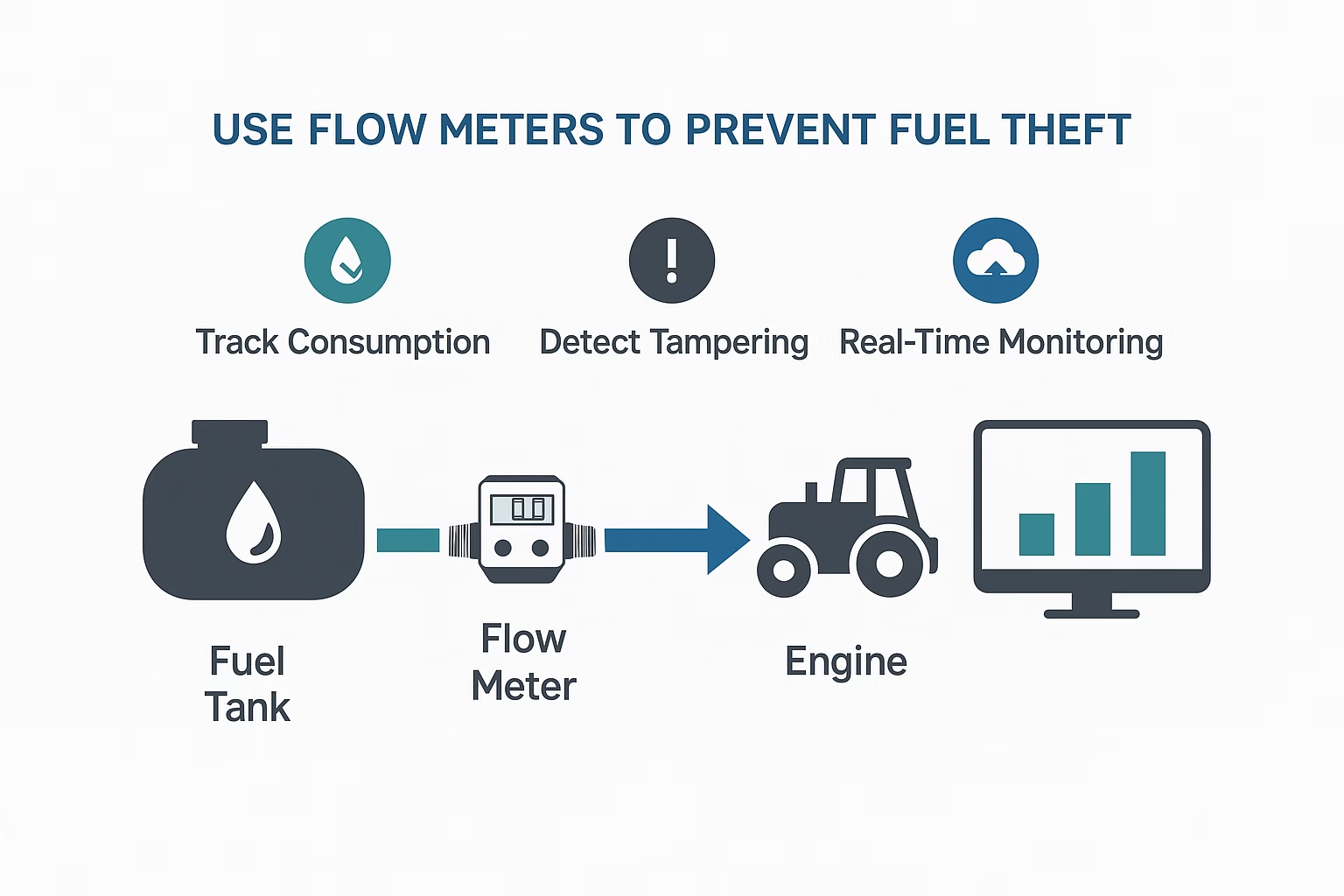

In this blog, we are going to discuss how we can use Flow Meters to prevent fuel theft in remote areas. Fuel theft is a significant concern in remote and industrial operations. Especially, where heavy equipment, generators, and transport vehicles consume large volumes of diesel. With sites often located far from central management and oversight. Fuel loss—whether through unauthorised siphoning, inaccurate logging, or manipulation. Quickly adds up to thousands of dollars in losses.

Fortunately, the integration of industrial fuel flow meters provides a powerful and practical solution to monitor, detect, and prevent fuel theft.

🔍 Why Fuel Theft Is Hard to Detect in Remote Sites

Remote operations such as mining camps, agricultural installations, and isolated generator stations often have:

- Minimal on-site supervision

- Irregular fuel deliveries

- Limited data transparency

- No real-time tracking systems

This makes it easier for tampering, siphoning, and inaccurate reporting to occur unnoticed—especially in areas with long shifts and rotating staff.

✅ How Flow Meters Help Prevent Fuel Theft

Modern fuel flow meters, such as the DFM Industrial Flow Meter, offer multiple features that make them ideal for securing remote fuel operations:

1. Accurate Measurement of Actual Fuel Used

Flow meters track the real-time volume of fuel flowing to the engine or generator. This data can be compared against delivery logs and expected usage to detect anomalies.

2. Tamper Detection and Event Logging

Tampering attempts, such as:

- Blowing air through the fuel line

- Applying strong magnets

- Reversing flow

can be automatically detected. Smart flow meters log these events in memory and flag them via CAN or display.

3. Built-In Counters for Interference Time

Some models feature a special interference timer. Firstly, it records how long a fuel meter was exposed to potential tampering or disruption. Including even if power was lost or the flow stopped.

4. Data Logging and Integration with Telematics

Fuel flow meters with CAN bus output (J1939/S6) can be integrated into fleet and asset telematics systems. This enables:

- Real-time alerts

- Remote data access

- Historical fuel consumption trends

- Automated reporting for fuel usage and theft detection

🛠 Practical Use Case: Mining and Construction Sites

In Australia, remote mining sites rely on diesel-powered equipment for everything from drills to water pumps. With refuelling trucks operating regularly and equipment running continuously, tracking fuel usage manually is nearly impossible.

Installing fuel flow meters on critical assets allows:

- Verification of fuel delivery quantities

- Monitoring of equipment fuel efficiency

- Immediate alerts if fuel is disappearing when machines are idle

This visibility helps reduce losses and increases accountability.

🔄 What About Fuel Level Sensors?

While fuel flow meters monitor fuel usage, fuel level sensors track the amount of fuel in the tank. Used together, they provide a full picture of fuel inventory and consumption.

📉 Fuel Level Sensors Help Detect:

- Sudden drops in tank volume when equipment is not running

- Inaccurate or falsified refuelling events

- Ongoing fuel theft from stationary tanks

By monitoring tank levels in real-time, fuel level sensors:

- Trigger alerts for unexpected losses

- Assist in scheduling refuelling

- Help verify actual fuel deliveries

🧠 Flow Meter + Level Sensor = Full Visibility

| Feature | Fuel Flow Meter | Fuel Level Sensor |

|---|---|---|

| Tracks engine fuel use | ✅ | ❌ |

| Detects tank level drops | ❌ | ✅ |

| Measures tank refills | ❌ | ✅ |

| Detects tampering | ✅ | ❌ |

| Tracks idle/optimal operation | ✅ | ❌ |

| Sends tank-level data | ❌ | ✅ |

When integrated with a telematics system, these two devices work together to eliminate fuel blind spots across remote and industrial environments.

📦 Choosing the Right Flow Meter for Anti-Theft Protection

When selecting a flow meter for theft prevention in remote operations, consider the following:

| Feature | Why It Matters |

|---|---|

| Tamper detection | Identifies manipulation attempts |

| Built-in battery | Operates in off-grid locations |

| CAN bus or pulse output | Enables remote integration |

| Rugged construction | Withstands harsh outdoor conditions |

| LCD display | On-site reading and troubleshooting |

The DFM Industrial Flow Meter checks all of these boxes and is trusted across industries including mining, construction, and logistics. Other models include Diesel Fuel Flow Meter, Heavy Machinery/Marine Flow Meter and our Wireless Fuel and Oil Models

🚀 Take Control of Your Fuel Usage

Fuel is one of your most valuable resources—and one of the easiest to lose without proper monitoring. Installing smart industrial fuel flow meters, alongside fuel level sensors, offers full visibility, transparency, and protection across remote operations.

If you’re managing diesel-powered equipment in isolated or industrial environments, talk to Metromatics about how to integrate fuel monitoring into your operations. We offer local expertise, technical support, and a full range of fuel management products to suit any site.

Looking for advice on how to get started?

📞 Contact us today to discuss how to use Flow Meters to prevent fuel theft in remote areas get a tailored recommendation.