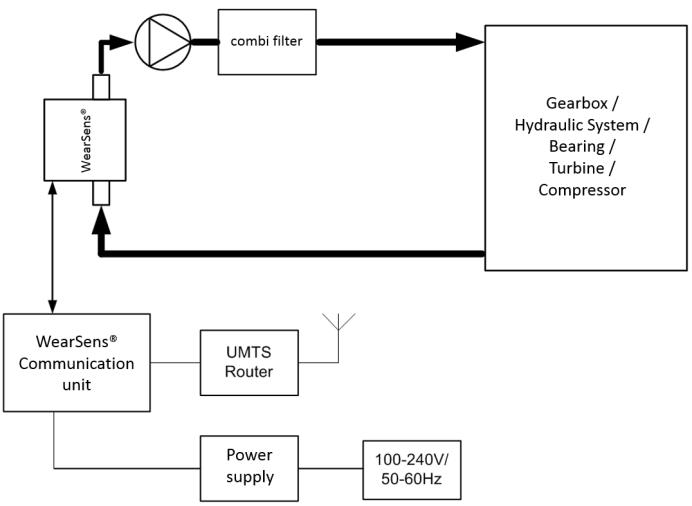

The Gearbox and Roller bearing Preventative Maintenance System is called the WearSens® Model WS3000. It measures a change in oil in Gear Boxes and Roller Bearings in heavy machinery. A change in oil is one of the precursors of particle shearing and pitting in the bearing raceway. Therefore, early detection can warn of potential damage before damage occurs.

Firstly, the WearSens® measures electrical conductivity. Using a compensation algorithm in neural network it accurately measures conductivity to 0.1 picosiemens per metre. Sensitivity measurement indicates a formation of compounds from broken molecules such as the presence of microparticles and consumptions of any additives.

Secondly, relative permittivity is a measure of the dielectric constant. The oil sensor decreases as additives are used up but will increase once all additives are consumed. Therefore, with the conductivity values, a clear picture emerges of the changes in the oil.

A unique feature of the system is that it provides online monitoring making it ideal for remote locations as measurements are transmitted via LAN, WLAN or Serial Interface.

Features of the Gearbox and Roller bearing Preventative Maintenance System include:

- Condition Based Maintenance providing huge cost savings

- Detects change in the system before damage starts and optimises load

- More sensitive than vibration monitoring and lab analysis

- Decentralised Web based monitoring system 24/7

- Easy to install and retro-fit

For more information click here for the brochure or contact us.