In Australia and New Zealand’s mining and quarrying operations – conditions are tough. Optimising fuel consumption, reducing downtime, and protecting high-value assets is crucial. Our heavy equipment monitoring solutions are designed to deliver. Information such as: accurate data on fuel usage, engine hours, and machinery performance — all in real-time.

Metromatics offers a complete fuel monitoring and telematics solution tailored for mining fleets, heavy machinery, and off-road equipment.

Real-Time Monitoring for Heavy Mining Equipment

Our solution integrates seamlessly with a wide range of mining machinery, including dump trucks, loaders, bulldozers, and gensets — enabling:

- Fuel consumption monitoring: Using DFM fuel flow meters, accurately measure fuel usage even in high-consumption equipment (up to 4000 L/h).

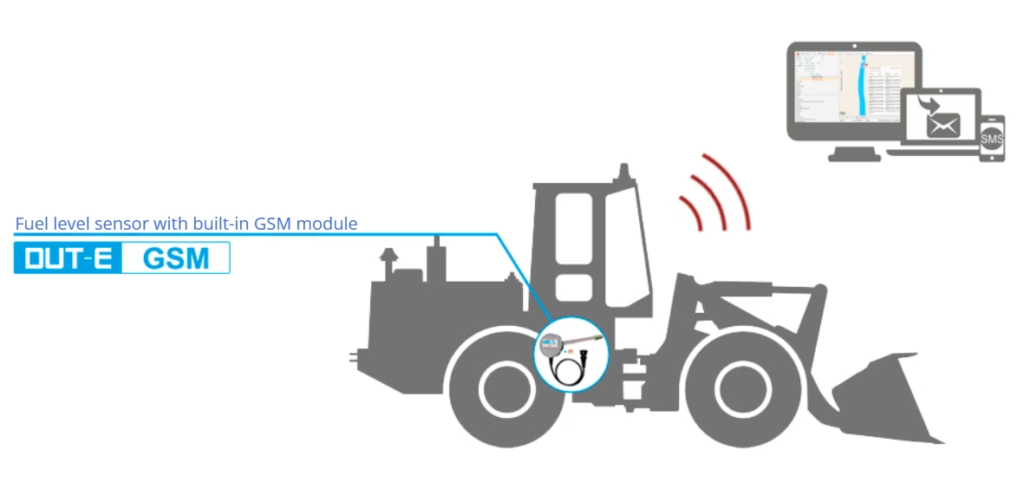

- Fuel theft detection: DUT-E fuel level sensors monitor tank levels to alert against sudden drops or suspicious usage patterns.

- Engine hour and idle time tracking: Gain visibility into engine operation time, including idling, optimal, and overload conditions.

- Cargo and axle load control: GNOM axle load sensors help ensure weight compliance and prevent overloading.

Fuel Monitoring System with Telematics Integration

All sensor data is collected by the CANUp telematics gateway. Which then transmits information via RS-485, CAN J1939, or BLE to a cloud-based monitoring platform (ORF4 or third-party systems). This setup provides:

- 🔧 Heavy equipment telemetry and diagnostics

- 📶 Remote asset tracking for mining sites

- 📊 Diesel consumption reports and analysis

- ⚠️ Instant alerts for fuel draining or overload

- 🔁 Predictive maintenance tools to minimise downtime

Built for Harsh Mining Environments

Firstly, hardware is for rugged environments. Therefore, making it ideal for the remote mining conditions of WA, QLD, and NZ quarry operations. Whether your site is a hard-rock mine or a mobile exploration camp. The system ensures reliable data collection in dust, vibration, and extreme temperatures.

Applications for Mining Fleet Managers and Operators

This mining fuel management system is used worldwide to:

- Improve accountability across large fleets

- Detect inefficiencies in fuel usage

- Prevent unauthorised fuel draining

- Monitor fuel flow, engine temperature, battery voltage, and more

- Manage total cost of operation per tonne of output

Why Choose Metromatics?

Metromatics offers local technical support, configuration assistance, and ongoing service to ensure your heavy machinery tracking system works seamlessly.

So, Ready to Get Started with Mining Telematics Today?

Want to cut fuel waste, reduce idle time, and boost your mining productivity?

👉 Contact Metromatics to learn more about our remote monitoring solutions for heaving equipment for the mining industry. Learn how they integrate with your CAN bus systems, telematics platforms, or remote generator installations.