This application note on compatible vacuum sensors has kindly been supplied by our friends, FUTEK.

For more information on this application or the products used, contact us.

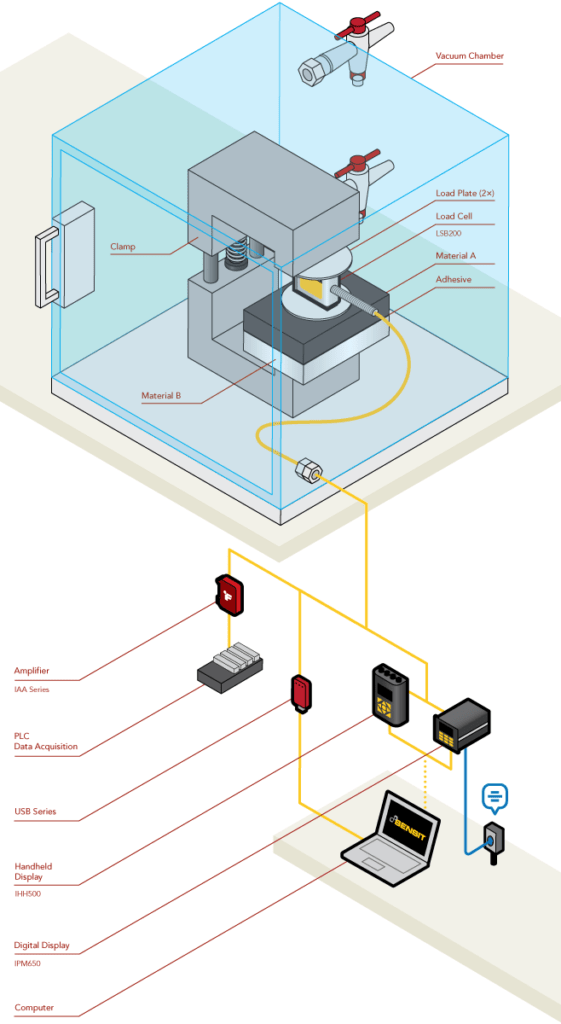

Vacuum Sensors Application Summary

Testing and producing products in a vacuum or space simulation environment. Firstly, it requires equipment that can operate without contaminating the chamber and interfering with results. Secondly, this requires low out gassing solutions. That generate vapour emissions within strictly controlled parameters. Lastly, for load and force testing and control, a vacuum compatible/low out gassing sensor is necessary for use in the vacuum environment.

Products in Use

Vacuum Compatible/Low Out gassing LSB200 Miniature S-Beam Jr. Load Cell paired with Instrumentation (USB220, IPM650 Panel Mount Display, IHH500 Handheld Display or IAA Series Strain Gauge Analogue Amplifier)

How it works

- In a vacuum environment, out gassing occurs within a material when trapped gasses or material elements boil off or sublimate as pressure falls below normal atmospheric pressures.

- Ideally, removal of gases is via the chamber. However, the gases will more often than not react with the vacuum chamber walls and any hardware inside the vacuum chamber.

- This causes staining and/or corrosion to the material in the chamber. These stains can occlude camera lenses and CCD elements, affect sensor readings, and damage components, often invalidating any measurements taken in the chamber.

- Therefore, it is critical that all components minimise out gassing to protect the integrity of the vacuum environment.

- For FUTEK’s low out gassing sensors. To reduce gassing use materials such as: Teflon cabling and wiring

- A LSB200 Miniature S Beam Load Cell measures the force in a vacuum environment. Of the two materials bonded together inside.

- Sensor placement is inline. With a clamp measuring the force of holding the two materials together.

- Therefore, the LSB200 cable mounted on the wall. Also into a bulkhead that helps maintain the vacuum environment and allows the signal to safely exit the chamber.

- The signal is then amplified via an IAA series Analogue Amplifier to be sent to a DAQ, displayed by an IPM650 Panel Mount Display, IHH500 Handheld Display, or logged using USB220 USB Output Module on a PC running SENSIT.

Finally, all FUTEK application illustrations are strictly conceptual. Please contact us with questions