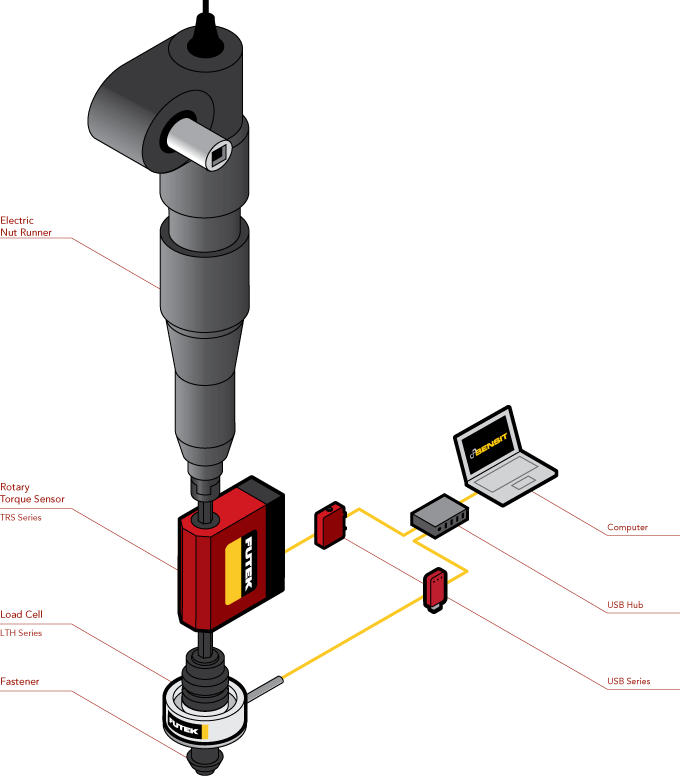

Accurate torque and tension monitoring is essential in precision bolt-fastening applications. This Nut Runner application, supplied by FUTEK. This shows how using a rotary torque sensor with a Donut/Thru-Hole Load Cell (LTH Series) gives useful information. It helps us understand the link between applied torque and bolt tension.

How It Works

In a standard bolt and nut setup, FUTEK’s LTH Series Donut Load Cell measures the axial force (thrust) while tightening. At the same time, a non-contact rotary torque sensor from the TRS Series is used to measure:

- Torque

- Angle of rotation

- Rotational speed

This setup enables accurate measurement of both the preload force (bolt tension) and the torque applied by the electric nut runner.

Real-Time Data Monitoring and Analysis

To monitor both sensor outputs simultaneously, the system is paired with:

- FUTEK USB520 – a compact, USB-powered signal conditioner supporting mV/V, amplified signals, and encoder inputs.

- FUTEK SENSIT™ Test and Measurement Software – enabling real-time graphing, data logging, and interpretation of force, torque, angle, and speed.

Together, these tools provide a comprehensive test and monitoring platform for R&D, quality control, and production-line applications.

Benefits of Using FUTEK Sensors in Nut Runner Systems

- Establishes a correlation between torque and bolt tension

- Enables real-time feedback for process optimisation

- Improves fastening accuracy and prevents over- or under-tightening

- Compact and industrial-grade components suited for harsh environments

Products Used

- LTH Series: Donut/Thru-Hole Load Cell

- TRS Series: Non-Contact Rotary Torque Sensor with Encoder

- USB Signal Conditioner Module – USB520 – Metromatics

- SENSIT™ Software: Test and Measurement Analysis Platform

Want to integrate precision torque and force monitoring into your fastening systems?

Contact us to learn more about FUTEK’s force and torque sensor solutions for electric nut runners.