Medical electronics demand absolute reliability. From patient monitors and infusion pumps to advanced imaging systems. Even minor electronic faults can compromise safety, performance, and compliance. As a result, manufacturers and service teams require a PCB Diagnostic Tool for Medical Devices. Especially one that can identify faults without introducing additional risk.

The Huntron Tracker provides a proven, non-invasive solution for diagnosing printed circuit assemblies (PCAs) used in critical medical equipment. Finally, by enabling power-off testing, it allows technicians to detect component-level faults safely, efficiently, and repeatably.

The Challenge of Diagnosing Medical Electronics PCBs

Medical PCAs are increasingly complex and present several diagnostic challenges:

- Powering a faulty PCB can cause irreversible damage

- Circuit diagrams are often unavailable or restricted

- Mixed-signal designs limit the effectiveness of traditional test methods

- Downtime directly impacts clinical operations and patient care

Consequently, a safe diagnostic method that does not rely on powered testing or schematics is essential.

Power-Off Analog Signature Analysis (ASA)

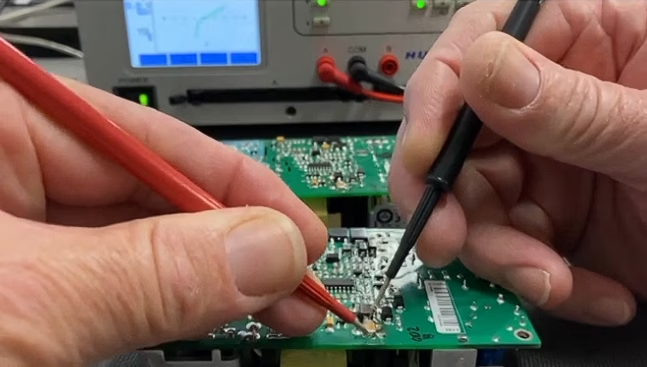

The Huntron Tracker operates as a PCB Diagnostic Tool for Medical Devices by using Analog Signature Analysis (ASA). This power-off technique applies a low-voltage AC signal to unpowered circuits and measures their electrical response.

Each component and circuit path produces a unique analog “signature.” By comparing these signatures to a known-good baseline, technicians can quickly identify faults such as:

- Shorted or open components

- Leaky semiconductors

- Damaged passive devices

- Assembly or connector faults

Because testing is performed with no power applied, sensitive medical electronics remain protected throughout the diagnostic process.

Huntron Tracker Models for Medical Device Applications

Huntron Tracker 3200S

The most advanced model, designed for high-reliability environments and automated workflows.

Key features:

- Expanded ASA measurement and analysis capability

- Two 64-pin IDC connectors for extensive test access

- Automated ASA testing when integrated with the Access 2 Prober

- Ideal for medical manufacturing, refurbishment, and advanced repair facilities

Huntron Tracker 2800S

A robust entry-level option for routine diagnostics and maintenance.

Key features:

- Two 40-pin IDC connectors

- Efficient scanning of connectors and ports using custom interfaces

- Well suited to service labs and biomedical engineering teams

Huntron Tracker 2800

A durable, straightforward benchtop solution focused on manual troubleshooting tasks while retaining core ASA functionality.

Preventative Maintenance and Refurbishment Verification

In addition, beyond fault diagnosis, the Huntron Tracker supports preventative maintenance programs by enabling baseline signature capture. Allowing these reference signatures can be stored and reused to:

- Detect early-stage component degradation

- Validate repaired or refurbished PCBs

- Confirm electronic integrity before returning equipment to service

This capability helps extend equipment lifespan, reduce repeat failures, and improve long-term reliability of medical systems.

Why Use a PCB Diagnostic Tool for Medical Devices?

Using a dedicated PCB Diagnostic Tool for Medical Devices delivers measurable operational benefits:

- Eliminates risk associated with powered testing

- Reduces troubleshooting time and guesswork

- Supports compliance and quality assurance processes

- Minimises equipment downtime

- Protects high-value and safety-critical medical electronics

Conclusion

For organisations responsible for the manufacture, repair, and maintenance of medical electronics, the Huntron Tracker offers a safe, proven, and highly effective diagnostic approach. By combining power-off testing with Analog Signature Analysis, it enables confident fault detection, preventative maintenance, and refurbishment verification—without compromising sensitive medical devices.

Finally, for more information, contact us.