ATI’s Prop Shaft Torque Measurement system can be installed on most size shafts and is field installable by the user.

Firstly, power to the transmitter and rotating electronics can be supplied several ways.

Below is an overview with the benefits of each method.

Low Power Digital Prop Shaft Telemetry System.

Firstly, power can be supplied by a rechargeable lithium cell, rechargeable Lithium battery packs, or standard and high temperature (Tadiran) non batteries. To extend battery life, the Transmitter continuously checks for control signals from the Receiver. When it detects that the Receiver is turned off or is out of range, the Transmitter automatically goes into an ultralow power Sleep mode. Therefore, conserving battery power. When in Sleep mode, it periodically wakes up to check for the presence of the Receiver’s control signal. When this signal is sensed, the Transmitter fully powers up and resumes transmitting sensor data.

Rechargeable Battery Powered Prop Shaft Telemetry System.

Power is supplied by an ATi provided, Lithium battery pack. The transmitter can be turned on and off remotely from the receiver. Additional features include transmitter status and battery level presented on the Model 2125B or 3125B Receiver display. Rechargeable Battery Powered Systems are also available in a Band-On version.

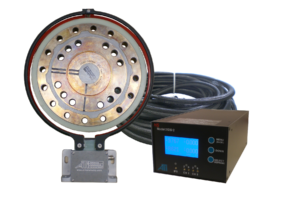

Inductively Powered Prop Shaft Telemetry System.

Power is supplied to the transmitter inductively for continuous, non-interrupted measurements. No batteries are required because the Induction Power Supply (IPS) delivers power through a stationary loop antenna to a rotating loop antenna. The rotating loop antenna and Induction Power Converter are embedded into the collar assembly. Additional features include transmitter status and induction power level presented on the Model 2125i(R) or 3125i(R) Receiver display.

For more information, contact us.