What Are Wireless Concrete Sensors?

Wireless concrete sensors are embedded or attached devices. That monitor the strength, temperature, and other critical performance metrics of concrete in real time — without requiring wired connections. These smart sensors transmit data wirelessly to cloud platforms or mobile apps. Therefore, enabling remote monitoring and analysis during curing, hardening, and in-service phases.

Converge has three advanced systems that give full visibility into concrete performance at any job site. These are the Signal Embedded Sensors and the Helix Long-Range System and the Embedded Signal Long Range Wireless Concrete Sensors.

Converge Signal® Embedded Sensors

Signal System

Embedded I Wire free I Plug and Play

Converge Helix® Long-Range System

Helix System

Long Range I Reusable

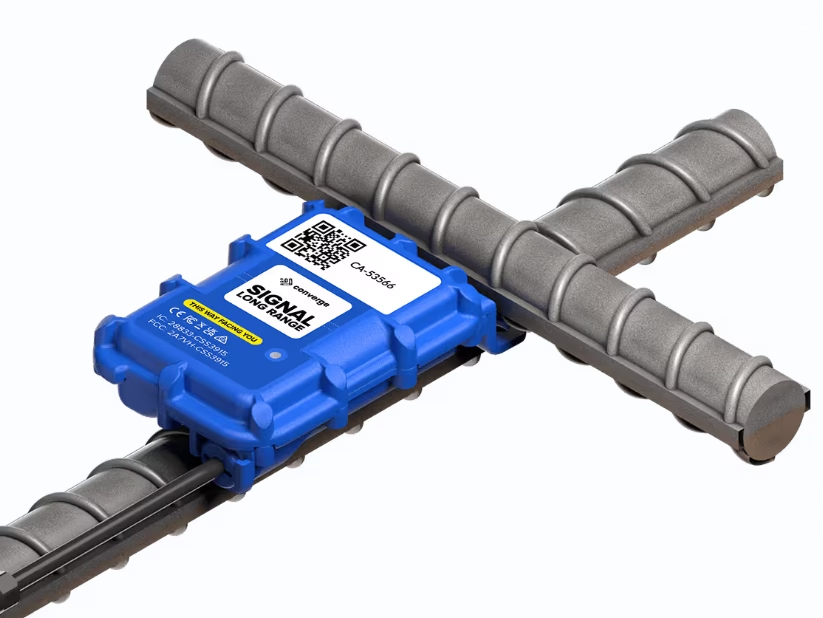

Signal Long Range

Long Range I Embedded I Wire free

How Wireless Concrete Sensors Work

Both the Signal® Embedded Sensors and Helix® and Signal Long-Range Systems measure concrete temperature and strength. They send this data in real time. However, each uses a different process.

The Signal range is a single-use, fully embedded sensor tied directly to the rebar. Whilst the Helix system is a reusable, long-range monitoring solution that connects to embedded probe tails. The Signal Long Range™ is a fully embedded, single-use long-range wireless concrete sensor. Designed for continuous internal monitoring across large pours.

To learn more about installation, data flow, and configuration, visit the dedicated pages for each system below:

Key Benefits of Wireless Concrete Sensors

Real-Time Monitoring & Alerts

Access live concrete performance data and make faster. Allowing you to make evidence-based decisions during curing and construction.Faster Project Timelines

Know exactly when concrete has reached target strength. Enabling earlier formwork removal and faster scheduling.Improved Quality & Safety

Continuous monitoring ensures consistent curing, reduces cracking risks, and enhances site safety.Automation & Data Integration

Eliminate manual data collection and centralise measurements in one digital dashboard.Sustainability Gains

AI-enhanced analysis optimises concrete mix designs. Therefore, helping lower carbon emissions while maintaining performance.Reusability

The Helix system’s reusable nodes reduce waste and provide cost-efficient monitoring across multiple pours.

Applications & Use Cases

Wireless concrete sensors are suitable for a wide range of construction and civil engineering projects, including:

Mass concrete pours and thermal differential monitoring

Post-tensioned or prestressed concrete structures

Foundations and deep structures

Tunnelling and underground works

Precast factories and off-site construction

Major civil infrastructure such as bridges, dams, and transport projects

Why Use Wireless Concrete Sensors?

Wireless concrete sensors provide builders and engineers with clear insights into what happens inside their concrete. This changes a hidden process into a data-driven and open workflow. They improve safety, accelerate schedules, and enhance quality by providing real-time insights that eliminate guesswork.

Converge wireless concrete sensors use automated data collection, AI analytics, and long-range wireless connections. They are now key tools for smart construction and digital site management in Australia.

Contact Us

Enhance your concrete monitoring capabilities with advanced Converge wireless concrete sensors. Contact our team today. Learn how this technology can improve quality, reduce risk, and accelerate timelines on your next project.