The DFM Industrial Fuel Flow Meter provides Accurate Fuel Monitoring for Industrial Engines, Generators & Heavy Machinery

The high accuracy DFM Industrial Fuel Flow Meter is a tamper-resistant device. Designed to measure diesel fuel consumption in engines, boilers, generators, and other industrial equipment. With its robust metal housing, wide flow rate range, and CAN bus output. It is ideal for heavy equipment fuel tracking, telematics integration, and industrial fuel management systems.

✅ Key Advantages

High-Accuracy Fuel Measurement

Measures actual fuel volume passing through, with accuracy up to ±0.25%.Tamper-Resistant Protection

Detects attempts to interfere with measurement (e.g. magnets, air blowing).Flexible Output Options

Available with CAN J1939/S6, pulse output, or as a standalone unit.Long-Term Operation

Up to 36 months battery life in standalone mode.Designed for Harsh Environments

Rugged enclosure rated IP54 for industrial and outdoor use.

📊 What Does the DFM Industrial Calculate?

The flow meter continuously calculates and logs:

Total fuel consumption

Instantaneous fuel flow rate

Engine operation time (idle, optimal, overload)

Tampering activity (magnetic, airflow, etc.)

Time under external interference

Battery charge level

Temperature in the measuring chamber

🔎 Flow Meter Display Information

The DFM Industrial with LCD display provides real-time feedback directly on the device:

Total Fuel Consumption (8-digit counter)

Instant Fuel Consumption (litres/hour)

Engine Time: Idle, Optimal, Overload

Tampering Alerts and Interference Time

Battery Percentage Remaining

Internal Temperature

Firmware Version

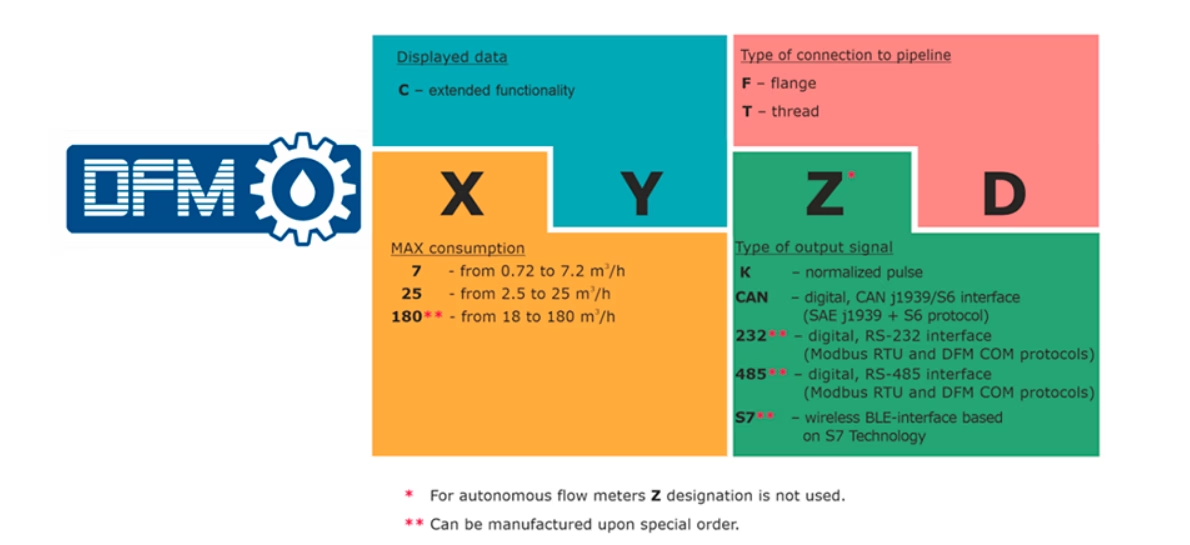

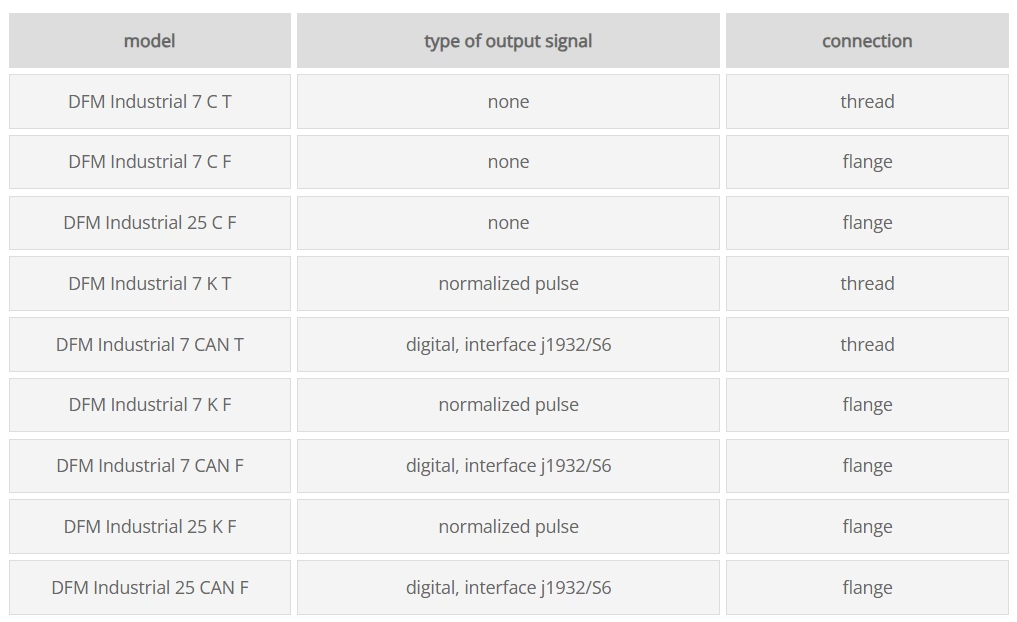

🧰 Available Models

🧪 Diagnostics & Configuration

Diagnostics features enable detailed analysis of engine fuel usage and attempts at tampering:

Interference logs with date/time stamp

Event counters for magnetic/airflow tampering

Engine state logs (overload/idle/optimal)

Configuration Tools (sold separately):

S6 BT Adapter – Bluetooth setup via smartphone app

S6 SK Adapter – USB setup via PC

MK DFM Mounting Kit – Ensures correct inline installation

GE Gas Eliminator – Removes air bubbles for more accurate readings

📐 Technical Specifications

| DFM Industrial 7 | DFM Industrial 25 | |

|---|---|---|

| Measurement Chamber Characteristics | ||

| Nominal Diametre DN, mm | 25 | 40 |

| Nominal Measuring Chamber Volume, L | 0.1 | 1.0 |

| Mean time before recalibration | 60000/10 | 60000/10 |

| Measurement range and accuracy | ||

| Starting* flow rate, m3/h | 0.02 | 0.5 |

| Minimum flow rate, m3/h | 0.72 | 2.5 |

| Maximum flow rate m3/h | 7.2 | 25 |

| Inaccuracy** up to % | +/-0.25 | +/-0.25 |

| Maximum Pressure | 1.6/6.4* MPa *on request for flange connection | 1.6/6.4* MPa *on request |

| Interface | CAN (J1939)/S6 Interface Pulse Output Autonomous without interface | CAN (J1939)/S6 Interface Pulse Output Autonomous without interface |

| Kinematic viscosity of liquid | 0.55-300 mm2/s (cSt) | 0.55-300 mm2/s (cSt) |

| Ambient Operation Temperature | from -20 to +60° | from -20 to +60° |

| Operating Principle | Oval Gears Rotation | Oval Gears Rotation |

| Connection to pipeline | flange, thread | flange, thread |

| Battery Lifetime | up to 36 months | up to 36 months |

🏗️ Applications

Diesel Generators and Gensets

Boilers and Industrial Burners

River and Sea Vessels

Mining and Construction Equipment

Fuel Tanker Delivery Monitoring

Remote Industrial Sites

📞 Need Help Choosing a Model?

Contact us now for more information on the High Accuracy DFM Industrial Flow Meters. We provide local support, installation advice, and configuration services for all application in Australia and New Zealand.

Fuel theft is more common than you think. Discover how installing a flow meter can provide peace of mind and measurable savings.