This case study on Performance and Efficiency Testing of Actuators was kindly provided by our friends Dewesoft. For more information on the products used in this case study, contact us.

A Dewesoft customer, LOGICDATA develops mechatronic system solutions for adjustable home and office furniture. The company constantly strives to create new and better technology. Implementing industry-leading solutions into their products, they have to rely a lot on internal testing. The company has created its own database for evaluating solutions. The flexibility of the DEWE-43A data acquisition system has simplified the daily work.

Company Introduction

LOGICDATA was founded as a company in 1994. It is based in the small town of Deutschslandsberg, located in southern Austria. Today it has over 330 employees in Austria, Slovenia, China, Croatia, and the USA.

The company uses a vast range of intelligent electronics, mechatronics, and embedded software solutions to produce adjustable furniture for homes and offices.

Performance and Efficiency Testing of Actuators

An actuator is responsible for moving and controlling the mechanisms or systems – it is the mover. More than 200 tests are performed for the actuator design to pass as OK.

LOGIDATA needs to have the ability to perform a wide variety of tests quickly and easily in different locations. The DEWE-43A DAQ system offers exactly this.

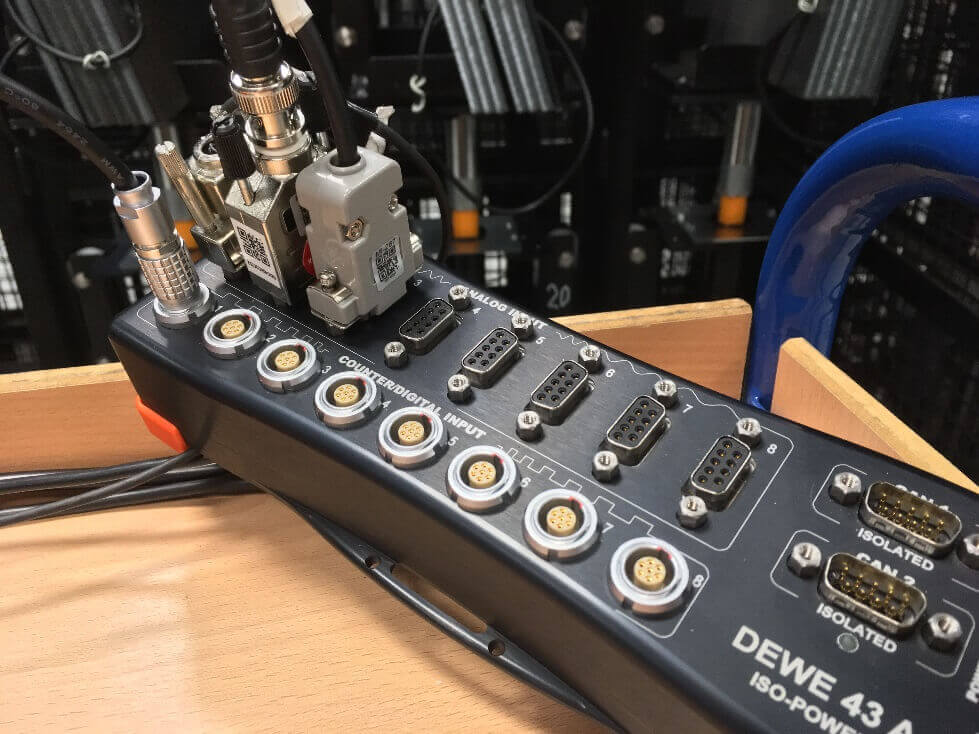

DEWE-43A Data Acquisition System

DEWE-43A weighs less than 1 kilogram and is small enough to fit in a hand. The DAQ instrument is light for maximum portability, but also tough and capable. Every unit is CNC machined out of a solid block of aluminium and offers 8 high-speed analog and 8 super-counter inputs. The instrument also offers an unmatched price/performance ratio.

DEWE-43A is suited for a wide range of dynamic data acquisition applications. In addition, the instrument includes advanced data acquisition, recording, and analysis software Dewesoft X. Dewesoft X DAQ software is developed around one core philosophy – one software for all testing applications. Therefore, this combination really makes DEWE-43A the Swiss Army Knife for test and measurement.

Dewesoft SuperCounter® Technology Explained

DEWE-43A data acquisition system also supports TEDS sensor standard (Transducer Electronic Data Sheet). The technology allows the engineers to quickly build the test setup onsite and perform different kinds of tests such as:

- motor performance tests,

- lifetime performance tests,

- acceleration/deceleration profile test.

Motor Performance and Lifetime Performance Tests

To be able to move furniture, a motor is needed. In this case a Permanent Magnet Synchronous Motor (PMSM). The motor’s field excitation is provided by permanent magnets on the rotor. A 3-phase motor is used with a company made the controller.

Equipment used:

- DEWE-43A: data acquisition system

- DEWESoft X: data acquisition software

- DSI-V-200: adapter for ±200V analog input

- LEM LTSR 15-NP: Current Sensor

- 1535 Peaktech: Power Supply 600W

- RRFL-I-1-n ETH: 1Nm Torque sensor

- HB-140M-2: Magtrol Hysteresis brake

- Self-made brake controller

A simple test device with a motor holder, torque and speed sensor and the brake is applied to test the motor performance. The current flow is monitored in each phase, DC supply current, and voltage, and this way the energy provided to the motor can be calculated. In addition, on the mechanical side, torque and speed are measured. Therefore, the mechanical energy going from the motor can then be calculated.

The tests run through different loads and speeds and all the data are collected. Dewesoft X data acquisition software enables the calculation of the efficiency of the motor and generation of the motor performance curve to live while doing a measurement.

Actuator Performance During Simulation of Lifetime

It is also important to LOGICDATA to know how the performance of the actuator may change over its lifetime. Therefore, different performance measurements are done during a live test of the actuator. For this, a portable measuring solution is significant, as the engineers have to move from actuator to actuator and perform the tests. Equipment used:

- DEWE-43A: data acquisition system

- DEWESoft X: data acquisition software

- As well as a DSI-V-200: adapter for ±200V analog input

- LEM LTSR 15-NP Current Sensor

- Company-made digital counter

- HBM U10M 2,5kN Force sensor

While the actuator is loaded with a defined load over the lifetime. The equipment is connected and the DC voltage current that is going into the actuator is measured. The engineers tap into the communication between the control box and actuator and contract a voltage peak every time the motor rotates.

The counter setup in Dewesoft X is used to instantly calculate motor speed. The force sensor is mounted under the actuator. The load the actuator needs to move is known.

In addition, the mechanical energy going out of the actuator can be calculated. Therefore, this information allows calculation of the actuator efficiency. At the end of the life test, results from the same actuator over its lifetime are compared and any changes noted.

Table Acceleration and Deceleration Profile

Acceleration and deceleration profile of the height-adjustable table plays a very important role in user experience and overall perception of the quality of the table. Therefore, different systems have been objectively and subjectively evaluated. This creates a guideline for future products. Equipment used:

- DEWE-43A: data acquisition system

- DEWESoft X: data acquisition software

- Variohm RF603: Laser distance sensor

Firstly, the laser was mounted on a special profile. This measured the distance to the tabletop. Secondly, the table was moved up and down. The position recorded. From this position, the acceleration and deceleration profile was extracted and compared to subjective evaluations.

Conclusion

System portability and flexibility are essential features for the LOGICDATA measurements. Seamless integration of data acquisition hardware and software brings unparalleled ease of use.

Finally, advanced mathematical formulas in the software calculates at real-time. This gives engineers the possibility to have a real-time, live view of calculated results and can adjust measured parameters during the test.

Therefore, the performance and efficiency testing of the actuators – delivers the desired results with the first measurement. At the end of the day, this saves a lot of time and money.