Real-time insight, AI prediction, and performance validation in one platform

The Converge ConcreteDNA® Platform is an intelligent concrete monitoring platform software, that brings all your wireless concrete data together.

It connects with the Signal® Embedded Sensors and Helix® Reusable Systems. Which provide real-time visibility of temperature, strength, and curing performance across every pour.

Designed for engineers, contractors, and precast manufacturers. ConcreteDNA® helps teams make faster, safer, and more sustainable decisions. Simply by combining live sensor data, automated reporting, and predictive AI analysis.

The Key Modules of ConcreteDNA Platform

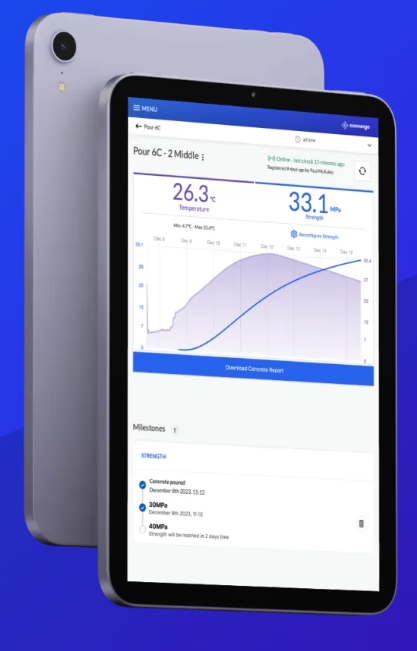

Cure™

Monitors concrete strength and temperature in real time. It provides live graphs, threshold alerts, and automatic reports. So you always know when your concrete is ready for formwork removal, post-tensioning, or load application.

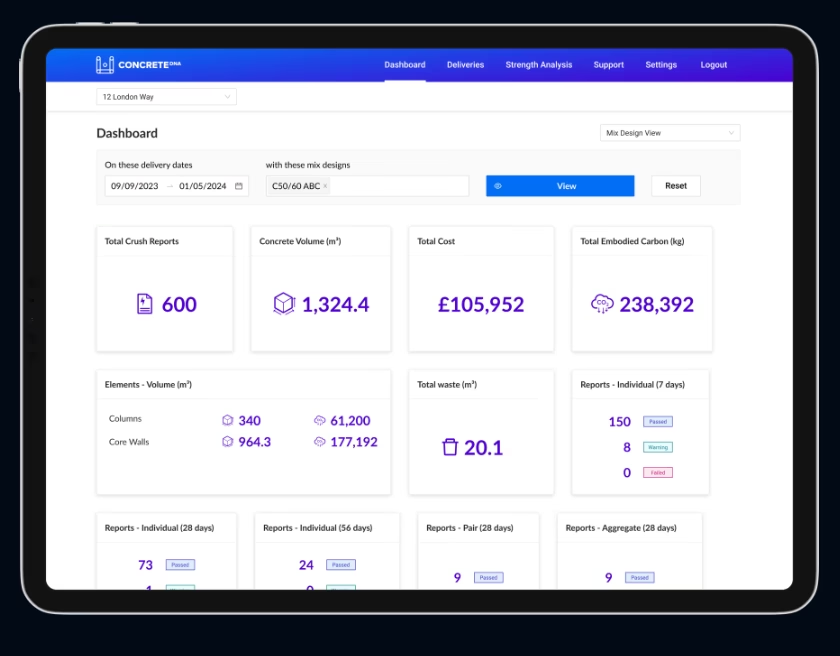

Mix AI™ (Beta)

Uses artificial intelligence to analyse historical and real-time data from your projects. It predicts performance outcomes and helps optimise mix designs. Therefore, reducing cement use, cost, and embodied carbon while maintaining structural quality.

Data Hub™

Automatically collects and synchronises data from multiple sources — including sensors, delivery records, and lab tests — into one secure platform. It eliminates manual data entry and simplifies QA/QC reporting across projects.

PrecastDNA™ (Beta) – Coming Soon

Purpose-built for precast manufacturers. This module enhances traceability and process control. Simply by linking mix design, curing conditions, and product performance in one unified dashboard.

Benefits

Make data-driven decisions based on real-time insight

Accelerate timelines with accurate strength milestone alerts

Improve quality through consistent digital monitoring

Reduce waste and carbon via smarter mix optimisation

Streamline QA/QC workflows with automated reporting

Typical Applications

Infrastructure and civil projects

Commercial and high-rise construction

Precast and manufacturing facilities

Bridges, tunnels, and transport structures

Contact Us

Bring the power of intelligent concrete monitoring to your project with Converge ConcreteDNA®.

Contact our team today. Learn how its AI-driven modules can help you deliver faster, safer, and more sustainable results across Australia.