Introduction: Why 6-Axis Force Measurement Matters

As machines, robots, autonomous systems, and medical devices become more advanced. Firstly, the need to accurately measure forces in multiple directions has never been greater. Traditional single-axis load cells can only capture one dimension of force. Therefore, making them unsuitable for modern systems that experience complex loads.

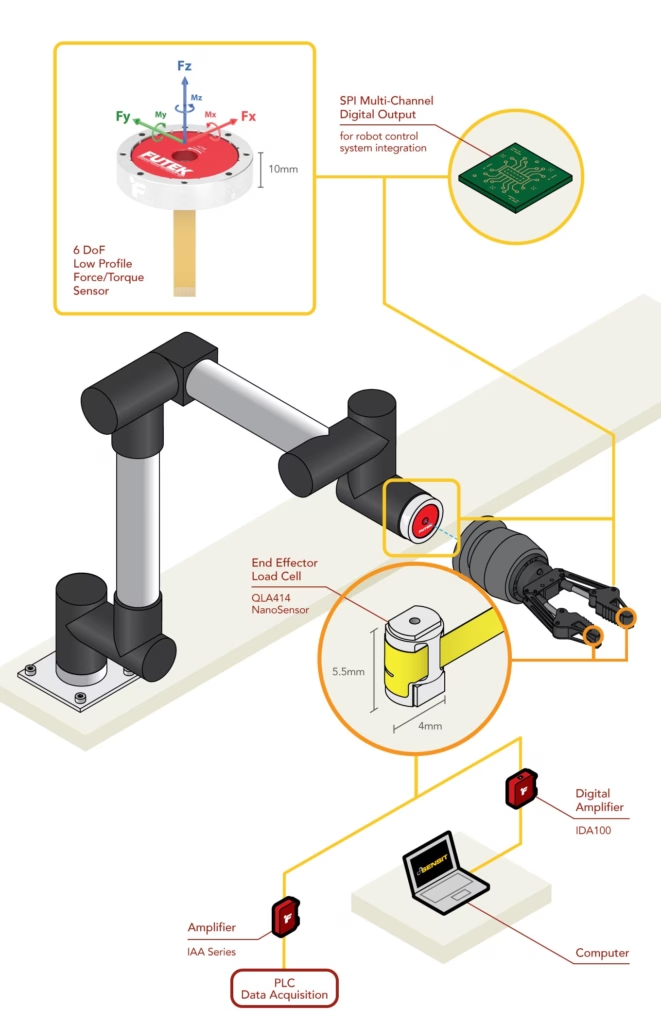

This is where 6-axis force sensors—also called multi-axis load cells or force-torque sensors—play a critical role.

FUTEK has recently released a detailed application overview. Explaining how 6-axis sensing improves accuracy, safety, and performance in a wide range of industries.

As the Australian and New Zealand distributor for FUTEK, Metromatics is excited to share these insights and explain what they mean for local engineers, researchers, and system designers.

What Is a 6-Axis Force Sensor?

A FUTEK 6-axis sensor measures forces and moments across all six degrees of freedom:

- Fx, Fy, Fz — Linear forces in X, Y, and Z

- Mx, My, Mz — Moments/torques around X, Y, and Z

This allows engineers to understand not only how much force is applied, but also how it is distributed across a structure or mechanism.

These sensors are engineered with strain-gauge technology and provide extremely high accuracy, even in the presence of off-axis or combined loads.

Key Insights from FUTEK’s Application Note

FUTEK’s latest application overview highlights several engineering challenges that 6-axis sensors solve. Below is a simplified breakdown tailored for Australian industry.

1. Enhanced Accuracy for Complex Mechanical Loads

In many systems—robotics, aerospace components, test rigs—forces rarely occur in one direction. A single-axis sensor can misinterpret combined loads, causing:

- inaccurate readings

- unpredictable system behaviour

- unsafe mechanical responses

A 6-axis load cell eliminates these errors, providing full visibility across all force directions and moments.

2. Improved Control in Robotics & Automation

Modern robotics relies heavily on real-time feedback to interact with people and environments safely.

A 6-axis sensor enables:

- precision force-feedback control

- improved gripping and manipulation

- safe human-robot interaction

- smooth teaching and motion learning

This makes it valuable for industrial cobots, surgical robots, research robotics, and automated manufacturing.

3. Better Structural and Mechanical Testing

Industries such as aerospace, automotive, defence, and research institutions require precise force feedback when validating components.

Use cases include:

- characterising new materials

- fatigue and lifetime testing

- structural verification in multiple dimensions

- validating actuator or mechanism response to complex loads

With a multi-axis sensor, engineers gain a complete picture of how a structure behaves under real-world conditions.

4. Advanced Force-Torque Sensing in Medical Devices

FUTEK sensors are used globally in high-precision medical applications, including:

- robotic surgery systems

- prosthetics and rehabilitation devices

- minimally-invasive instruments

- haptic control systems

The ability to capture tiny, multi-directional forces results in safer, more responsive systems.

5. Compact, Lightweight Design for Embedded Applications

FUTEK’s 6-axis sensors are remarkably compact. This enables integration into:

- UAV platforms

- research robots

- autonomous vehicles

- wearable devices

- biomechanical measurement systems

Their durability and high signal integrity make them ideal for embedded force-feedback systems.

Real-World Applications Across Australia & New Zealand

Local industries that benefit from 6-axis sensors include:

Defence & Aerospace

- structural component testing

- UAV control surfaces

- autonomous platform sensing

- actuator and mechanism verification

Mining & Heavy Industry

- equipment fatigue monitoring

- feedback for automated machinery

- vibration and load interaction analysis

Universities & Research

- biomechanics

- robotics development

- materials testing

Medical Technology Development

- surgical robots

- device prototyping

- precision movement verification

Why Choose FUTEK for Multi-Axis Measurement?

FUTEK is globally known for:

- extremely high accuracy and repeatability

- compact, robust mechanical design

- industry-leading strain-gauge technology

- quality manufacturing in the USA

- seamless integration with amplifiers, DAQ, and software

Their engineering documentation—including this application note—provides outstanding clarity for design and testing teams.

Metromatics: Your Local FUTEK Partner in Australia & New Zealand

As the distributor for FUTEK across Australia and New Zealand, Metromatics provides:

- local sales and engineering assistance

- product selection support

- integration guidance

- calibration and accessory advice

- fast access to application notes, datasheets, and real product expertise

If your team is looking into 6-axis sensing for robotics, research, industrial automation, or product development, we can help. We will find the right FUTEK model and integration path for you.

Want to know more?

Ready to learn more about how 6-axis force sensors can improve accuracy and control in your application?

Contact Metromatics to learn more