The GNOM DDE axle load pressure sensor. Firstly, it converts air suspension pressure into an electrical signal that represents axle load in real time. Therefore, fleet operators, vehicle manufacturers, and system integrators use the sensor to monitor loading conditions, protect vehicle components, and improve operational compliance.

Engineered for harsh mobile environments. Including heavy vehicles operating in mining, transport, agriculture, and infrastructure sectors. As a result, it provides stable measurement performance under vibration, temperature variation, and continuous duty cycles. The GNOM DDE integrates directly with vehicle telematics, onboard displays, or control systems.

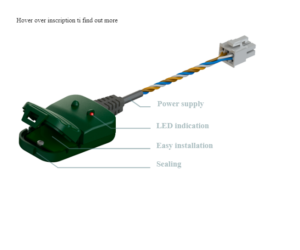

Key Features

Designed specifically for axle load measurement via air suspension pressure

Rugged construction for mobile and off-road environments

Stable pressure measurement for dynamic vehicle conditions

Electrical output suitable for telematics and onboard systems

High resistance to vibration, moisture, and contaminants

Compact form factor for integration into existing pneumatic systems

Long-term measurement stability for continuous fleet operation

Applications and Use Cases

Heavy vehicle axle load monitoring

Overload detection and prevention systems

Fleet compliance and mass management

Mining and quarry vehicles

Agricultural and forestry machinery

Transport and logistics fleets

Vehicle OEM and retrofit load monitoring solutions

Technical Specifications

| Parameter | Specification |

|---|---|

| Measurement principle | Air suspension pressure measurement |

| Measured medium | Compressed air |

| Output signal | Model dependent |

| Supply voltage | Model dependent |

| Pressure range | Model dependent |

| Accuracy | Model dependent |

| Operating temperature | Model dependent |

| Environmental protection | Designed for harsh mobile environments |

| Electrical connection | Model dependent |

| Mechanical connection | Pneumatic fitting, model dependent |

Note: Detailed specifications vary by configuration and are available on request.

Certifications and Compliance

Designed for use in commercial and industrial vehicle environments

Compliance details available on request, depending on configuration and market requirements

Installation and Deployment

Installed directly into the vehicle air suspension system

Requires connection to existing pneumatic lines

Electrical connection to telematics unit, display, or control system

Suitable for permanent installation on mobile equipment

Calibration performed at system level, depending on vehicle configuration

Lead Times and Local Support

Lead times vary depending on configuration and project requirements. Supplied and supported locally by Metromatics. Whom provide technical assistance, documentation, and integration support within Australia.

Why Metromatics

Specialist supplier of vehicle sensing and telematics components

Local engineering and technical support

Experience supporting fleet, mining, and industrial customers

Direct access to manufacturer-approved products and documentation

Specify the GNOM DDE axle load pressure sensor for accurate, durable axle load measurement in demanding vehicle environments. Contact Metromatics for configuration guidance, technical documentation, and local support.

Frequently Asked Questions (FAQ)

How does the GNOM DDE measure axle load?

The GNOM DDE measures air pressure within the vehicle’s air suspension system. This pressure directly correlates to axle load. Therefore, the connected system calculates load values.

Is the GNOM DDE suitable for on-road and off-road vehicles?

Yes. Designed for tough mobile environments. It works well on on-road trucks and off-road vehicles. These vehicles are used in mining, agriculture, and industry.

Can it be used with existing telematics systems?

Yes. The GNOM DDE interfaces with telematics platforms, onboard displays, and vehicle control systems. However, output type and wiring configuration are model dependent and must be matched to the target system.

Does the sensor provide direct weight readings?

No. The sensor outputs pressure data. Consequently, the connected system calculates axle load or weight values using calibration parameters specific to the vehicle and suspension configuration.

Is calibration required after installation?

Yes. System-level calibration is required to ensure accurate axle load calculations. As a result, calibration procedures vary depending on vehicle type and suspension design.

What maintenance does the GNOM DDE require?

The sensor requires minimal maintenance. Nevertheless, periodic inspection of pneumatic connections and electrical wiring is recommended as part of standard vehicle maintenance practices.

Can the sensor be retrofitted to existing vehicles?

Yes. The GNOM DDE supports retrofit installations. However, the vehicle must have with air suspension and compatible electronic systems.

What environmental conditions can the sensor operate in?

The sensor operates continuously in environments subject to vibration, dust, moisture, and temperature variation. Consequently, it suits demanding heavy vehicle and off-highway applications.