FUTEK Load Cells and Force Sensors available from Metromatics

-

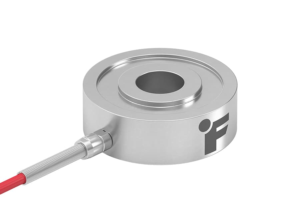

Accurate Universal Pancake Load Cell LCF400

Read more about Accurate Universal Pancake Load Cell LCF400 -

Automotive Pedal Force Load Cell – LAU220

Read more about Automotive Pedal Force Load Cell - LAU220 -

Automotive Pedal Force Sensor – LAU200

Read more about Automotive Pedal Force Sensor - LAU200 -

Biaxial Load Sensor MBA400

Read more about Biaxial Load Sensor MBA400 -

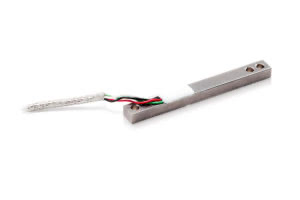

Cantilever Bending Beam Load Cell LBB200

Read more about Cantilever Bending Beam Load Cell LBB200 -

Car Shift Stick Sensor MAU300

Read more about Car Shift Stick Sensor MAU300 -

Digital Miniature S-Beam Load Cell LSB 206

Read more about Digital Miniature S-Beam Load Cell LSB 206 -

Donut Through-Hole Load Cell LTH 400

Read more about Donut Through-Hole Load Cell LTH 400 -

Donut Through-Hole Load Cell LTH300

Read more about Donut Through-Hole Load Cell LTH300 -

Donut Through-Hole Load Cell LTH350

Read more about Donut Through-Hole Load Cell LTH350 -

Fatigue rated load cells LCB200

Read more about Fatigue rated load cells LCB200