Enhancing COTS Boards with Analog to Digital Conversion: A Dive into Acromag’s Techniques

In a technology-driven world, the precision and efficiency of data conversion from analog to digital (A to D) and vice versa have become imperative. A Commercial Off-The-Shelf (COTS) board enhanced with an a to d converter (ADC) can make a huge difference between the analog and digital realms.

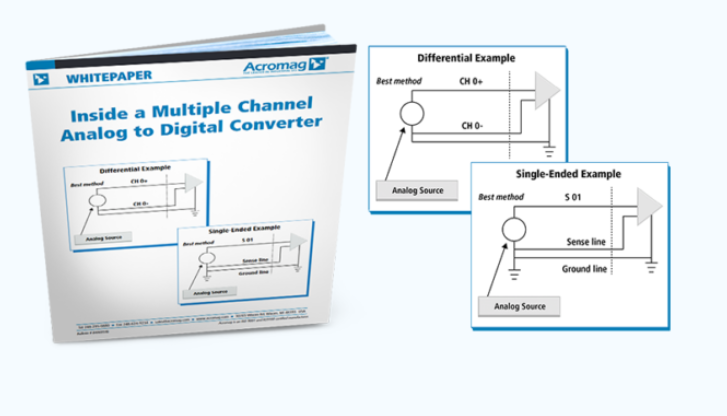

Acromag’s white paper titled “Inside a Multiple Channel Analog to Digital Converter” sheds light on common techniques to introduce A/D conversion in COTS boards, specifically highlighting operation during conversion. Acromag’s mPCIe-based AcroPack AP323 and AP341, along with the multi-function XMC module XMC730, serve as exemplar platforms for these techniques.

A/D Sampling Techniques:

Multiplexing Inputs:

- Implementing A/D conversion can be cost-effective by employing a singular ADC component and routing various signal combinations to the ADC’s input through multiplexing. This setup can accommodate a myriad of inputs including single-ended or differential inputs, internally-derived calibration voltages, or a local common reference known as “SENSE”.

- Although the ADC has high-speed performance. The speed per channel is proportional to the number of points being multiplexed. For instance, on Acromag’s mPCIe-based AcroPack AP323 and PMC330, the ADC samples at a rate of 125 KHz, but with 32 channels multiplexed, the throughput for individual channels results to around 4 KHz.

Simultaneous A/D Conversion:

- Contrary to multiplexing, having multiple ADCs, each dedicated to a singular input line. Therefore, this allows for simultaneous A/D conversion. This is essential when a “snapshot in time” of values across multiple inputs is desired. However, this necessitates temporary storage of converted values. Until the host computer can ferry them across the bus to the working memory for processing.

- Acromag’s AcroPack AP341 and PMC341 exhibit a “sample-and-hold” front-end, capable of performing 8 simultaneous conversions, then storing the values temporarily. Augmented with two 512-sample FIFO buffers, the AP341 ensures multiple simultaneous samples are recorded whilst awaiting data transfer by the host computer.

Wiring Techniques:

- The choice between differential and single-ended wiring hinges on the proximity of the analog source to the chassis hosting the A/D converter. Differential wiring is advocated when a stable common ground plane can’t be confidently established due to distance. On the flip side, in single-ended mode, a stable common ground plane is requisite.

Differential A/D Inputs:

- Utilising a multiplexer in differential mode enables effective use of the differential signal from the external source to establish a common mode on the local board. This setup is particularly beneficial in scenarios where a common stable ground plane can’t be confidently established.

Single-Ended A/D Inputs:

- In this mode, the signal to be converted is referenced to the “SENSE” line. Therefore, which connects to the system common ground when the source is in close proximity to the A/D board.

Operation During Conversion: During both differential and single-ended conversions, the analog value is momentarily frozen by a sample-and-hold circuit as conversion commences. This operation is critical for accurate data conversion and ensuring the integrity of the data being processed.

Exploring Acromag’s A to D Converters:

Acromag offers a myriad of A/D converters and modules to cater to diverse needs. Some of them include:

- AcroPack Mini PCIe-Based Interface I/O Boards like AP323, AP341, and AP342.

- Industry Pack Mezzanine I/O Modules such as IP330A and IP340.

- PCI I/O Boards like APC330 .

- PMC Modules and PMC Boards including PMC330 and PMC341.

- XMC Boards like XMC730.

In summary, implementing Analog to Digital conversion on a COTS board is addable in multiple ways. Each with its unique advantages and trade-offs. Acromag’s offerings provide a versatile and robust platform for integrating and leveraging A/D conversion. Therefore, making it a breeze for system designers to attain the desired balance between cost, speed, and performance.

Finally, Metromatics proudly sell, service and support the Acromag product range in Australia and New Zealand.